The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 17 – Mold Frames and Permanent Frames 191<br />

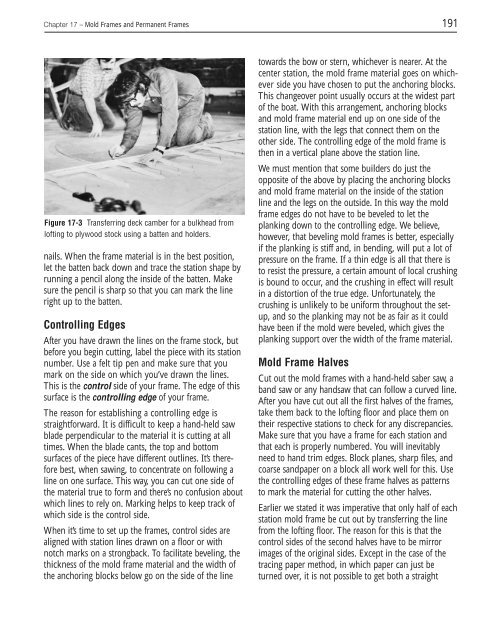

Figure 17-3 Transferring deck camber for a bulkhead from<br />

lofting to plywood stock using a batten and holders.<br />

nails. When the frame material is in the best positi<strong>on</strong>,<br />

let the batten back down and trace the stati<strong>on</strong> shape by<br />

running a pencil al<strong>on</strong>g the inside of the batten. Make<br />

sure the pencil is sharp so that you can mark the line<br />

right up to the batten.<br />

C<strong>on</strong>trolling Edges<br />

After you have drawn the lines <strong>on</strong> the frame stock, but<br />

before you begin cutting, label the piece with its stati<strong>on</strong><br />

number. Use a felt tip pen and make sure that you<br />

mark <strong>on</strong> the side <strong>on</strong> which you’ve drawn the lines.<br />

This is the c<strong>on</strong>trol side of your frame. <str<strong>on</strong>g>The</str<strong>on</strong>g> edge of this<br />

surface is the c<strong>on</strong>trolling edge of your frame.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> reas<strong>on</strong> for establishing a c<strong>on</strong>trolling edge is<br />

straightforward. It is difficult to keep a hand-held saw<br />

blade perpendicular to the material it is cutting at all<br />

times. When the blade cants, the top and bottom<br />

surfaces of the piece have different outlines. It’s therefore<br />

best, when sawing, to c<strong>on</strong>centrate <strong>on</strong> following a<br />

line <strong>on</strong> <strong>on</strong>e surface. This way, you can cut <strong>on</strong>e side of<br />

the material true to form and there’s no c<strong>on</strong>fusi<strong>on</strong> about<br />

which lines to rely <strong>on</strong>. Marking helps to keep track of<br />

which side is the c<strong>on</strong>trol side.<br />

When it’s time to set up the frames, c<strong>on</strong>trol sides are<br />

aligned with stati<strong>on</strong> lines drawn <strong>on</strong> a floor or with<br />

notch marks <strong>on</strong> a str<strong>on</strong>gback. To facilitate beveling, the<br />

thickness of the mold frame material and the width of<br />

the anchoring blocks below go <strong>on</strong> the side of the line<br />

towards the bow or stern, whichever is nearer. At the<br />

center stati<strong>on</strong>, the mold frame material goes <strong>on</strong> whichever<br />

side you have chosen to put the anchoring blocks.<br />

This changeover point usually occurs at the widest part<br />

of the boat. With this arrangement, anchoring blocks<br />

and mold frame material end up <strong>on</strong> <strong>on</strong>e side of the<br />

stati<strong>on</strong> line, with the legs that c<strong>on</strong>nect them <strong>on</strong> the<br />

other side. <str<strong>on</strong>g>The</str<strong>on</strong>g> c<strong>on</strong>trolling edge of the mold frame is<br />

then in a vertical plane above the stati<strong>on</strong> line.<br />

We must menti<strong>on</strong> that some builders do just the<br />

opposite of the above by placing the anchoring blocks<br />

and mold frame material <strong>on</strong> the inside of the stati<strong>on</strong><br />

line and the legs <strong>on</strong> the outside. In this way the mold<br />

frame edges do not have to be beveled to let the<br />

planking down to the c<strong>on</strong>trolling edge. We believe,<br />

however, that beveling mold frames is better, especially<br />

if the planking is stiff and, in bending, will put a lot of<br />

pressure <strong>on</strong> the frame. If a thin edge is all that there is<br />

to resist the pressure, a certain amount of local crushing<br />

is bound to occur, and the crushing in effect will result<br />

in a distorti<strong>on</strong> of the true edge. Unfortunately, the<br />

crushing is unlikely to be uniform throughout the setup,<br />

and so the planking may not be as fair as it could<br />

have been if the mold were beveled, which gives the<br />

planking support over the width of the frame material.<br />

Mold Frame Halves<br />

Cut out the mold frames with a hand-held saber saw, a<br />

band saw or any handsaw that can follow a curved line.<br />

After you have cut out all the first halves of the frames,<br />

take them back to the lofting floor and place them <strong>on</strong><br />

their respective stati<strong>on</strong>s to check for any discrepancies.<br />

Make sure that you have a frame for each stati<strong>on</strong> and<br />

that each is properly numbered. You will inevitably<br />

need to hand trim edges. Block planes, sharp files, and<br />

coarse sandpaper <strong>on</strong> a block all work well for this. Use<br />

the c<strong>on</strong>trolling edges of these frame halves as patterns<br />

to mark the material for cutting the other halves.<br />

Earlier we stated it was imperative that <strong>on</strong>ly half of each<br />

stati<strong>on</strong> mold frame be cut out by transferring the line<br />

from the lofting floor. <str<strong>on</strong>g>The</str<strong>on</strong>g> reas<strong>on</strong> for this is that the<br />

c<strong>on</strong>trol sides of the sec<strong>on</strong>d halves have to be mirror<br />

images of the original sides. Except in the case of the<br />

tracing paper method, in which paper can just be<br />

turned over, it is not possible to get both a straight