The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 23 – Strip Plank Laminated Veneer and Strip Composite C<strong>on</strong>structi<strong>on</strong> 275<br />

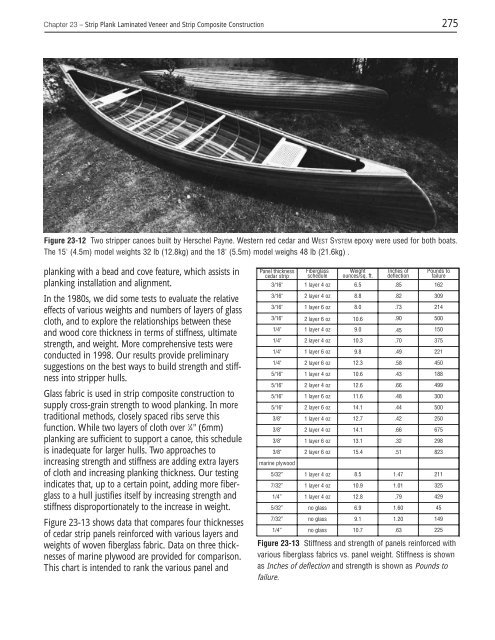

Figure 23-12 Two stripper canoes built by Herschel Payne. Western red cedar and <strong>WEST</strong> <strong>SYSTEM</strong> epoxy were used for both boats.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> 15' (4.5m) model weights 32 lb (12.8kg) and the 18' (5.5m) model weighs 48 lb (21.6kg) .<br />

planking with a bead and cove feature, which assists in<br />

planking installati<strong>on</strong> and alignment.<br />

In the 1980s, we did some tests to evaluate the relative<br />

effects of various weights and numbers of layers of glass<br />

cloth, and to explore the relati<strong>on</strong>ships between these<br />

and wood core thickness in terms of stiffness, ultimate<br />

strength, and weight. More comprehensive tests were<br />

c<strong>on</strong>ducted in 1998. Our results provide preliminary<br />

suggesti<strong>on</strong>s <strong>on</strong> the best ways to build strength and stiffness<br />

into stripper hulls.<br />

Glass fabric is used in strip composite c<strong>on</strong>structi<strong>on</strong> to<br />

supply cross-grain strength to wood planking. In more<br />

traditi<strong>on</strong>al methods, closely spaced ribs serve this<br />

functi<strong>on</strong>. While two layers of cloth over 1 ⁄4" (6mm)<br />

planking are sufficient to support a canoe, this schedule<br />

is inadequate for larger hulls. Two approaches to<br />

increasing strength and stiffness are adding extra layers<br />

of cloth and increasing planking thickness. Our testing<br />

indicates that, up to a certain point, adding more fiberglass<br />

to a hull justifies itself by increasing strength and<br />

stiffness disproporti<strong>on</strong>ately to the increase in weight.<br />

Figure 23-13 shows data that compares four thicknesses<br />

of cedar strip panels reinforced with various layers and<br />

weights of woven fiberglass fabric. Data <strong>on</strong> three thicknesses<br />

of marine plywood are provided for comparis<strong>on</strong>.<br />

This chart is intended to rank the various panel and<br />

Panel thickness<br />

cedar strip<br />

Fiberglass<br />

schedule<br />

Weight<br />

ounces/sq. ft.<br />

Inches of<br />

deflecti<strong>on</strong><br />

Pounds to<br />

failure<br />

3/16" 1 layer 4 oz 6.5 .85 162<br />

3/16" 2 layer 4 oz 8.8 .82 309<br />

3/16" 1 layer 6 oz 8.0 .73 214<br />

3/16" 2 layer 6 oz 10.6 .90 500<br />

1/4" 1 layer 4 oz 9.0 .45 150<br />

1/4" 2 layer 4 oz 10.3 .70 375<br />

1/4" 1 layer 6 oz 9.8 .49 221<br />

1/4" 2 layer 6 oz 12.3 .58 450<br />

5/16" 1 layer 4 oz 10.6 .43 188<br />

5/16" 2 layer 4 oz 12.6 .66 499<br />

5/16" 1 layer 6 oz 11.6 .48 300<br />

5/16" 2 layer 6 oz 14.1 .44 500<br />

3/8" 1 layer 4 oz 12.7 .42 250<br />

3/8" 2 layer 4 oz 14.1 .66 675<br />

3/8" 1 layer 6 oz 13.1 .32 298<br />

3/8" 2 layer 6 oz 15.4 .51 823<br />

marine plywood<br />

5/32” 1 layer 4 oz 8.5 1.47 211<br />

7/32” 1 layer 4 oz 10.9 1.01 325<br />

1/4” 1 layer 4 oz 12.8 .79 429<br />

5/32” no glass 6.9 1.60 45<br />

7/32” no glass 9.1 1.20 149<br />

1/4” no glass 10.7 .63 225<br />

Figure 23-13 Stiffness and strength of panels reinforced with<br />

various fiberglass fabrics vs. panel weight. Stiffness is shown<br />

as Inches of deflecti<strong>on</strong> and strength is shown as Pounds to<br />

failure.