The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 7 – Estimating Materials and Labor 53<br />

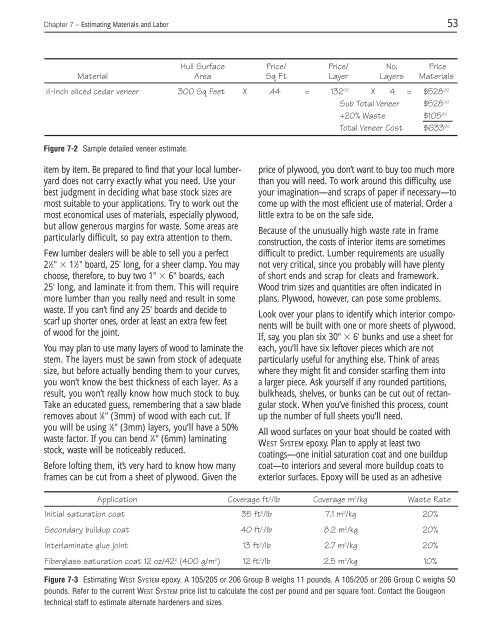

Hull Surface Price/ Price/ No. Price<br />

Material Area Sq Ft Layer Layers Materials<br />

1 ⁄8-Inch sliced cedar veneer 300 Sq Feet X .44 = 132 00 X 4 = $528 00<br />

Figure 7-2 Sample detailed veneer estimate.<br />

item by item. Be prepared to find that your local lumberyard<br />

does not carry exactly what you need. Use your<br />

best judgment in deciding what base stock sizes are<br />

most suitable to your applicati<strong>on</strong>s. Try to work out the<br />

most ec<strong>on</strong>omical uses of materials, especially plywood,<br />

but allow generous margins for waste. Some areas are<br />

particularly difficult, so pay extra attenti<strong>on</strong> to them.<br />

Few lumber dealers will be able to sell you a perfect<br />

21 ⁄2" � 11 ⁄2" board, 25' l<strong>on</strong>g, for a sheer clamp. You may<br />

choose, therefore, to buy two 1" � 6" boards, each<br />

25' l<strong>on</strong>g, and laminate it from them. This will require<br />

more lumber than you really need and result in some<br />

waste. If you can’t find any 25' boards and decide to<br />

scarf up shorter <strong>on</strong>es, order at least an extra few feet<br />

of wood for the joint.<br />

You may plan to use many layers of wood to laminate the<br />

stem. <str<strong>on</strong>g>The</str<strong>on</strong>g> layers must be sawn from stock of adequate<br />

size, but before actually bending them to your curves,<br />

you w<strong>on</strong>’t know the best thickness of each layer. As a<br />

result, you w<strong>on</strong>’t really know how much stock to buy.<br />

Take an educated guess, remembering that a saw blade<br />

removes about 1 ⁄8" (3mm) of wood with each cut. If<br />

you will be using 1 ⁄8" (3mm) layers, you’ll have a 50%<br />

waste factor. If you can bend 1 ⁄4" (6mm) laminating<br />

stock, waste will be noticeably reduced.<br />

Before lofting them, it’s very hard to know how many<br />

frames can be cut from a sheet of plywood. Given the<br />

Sub Total Veneer $528 00<br />

+20% Waste $105 60<br />

Total Veneer Cost $633 60<br />

price of plywood, you d<strong>on</strong>’t want to buy too much more<br />

than you will need. To work around this difficulty, use<br />

your imaginati<strong>on</strong>—and scraps of paper if necessary—to<br />

come up with the most efficient use of material. Order a<br />

little extra to be <strong>on</strong> the safe side.<br />

Because of the unusually high waste rate in frame<br />

c<strong>on</strong>structi<strong>on</strong>, the costs of interior items are sometimes<br />

difficult to predict. Lumber requirements are usually<br />

not very critical, since you probably will have plenty<br />

of short ends and scrap for cleats and framework.<br />

Wood trim sizes and quantities are often indicated in<br />

plans. Plywood, however, can pose some problems.<br />

Look over your plans to identify which interior comp<strong>on</strong>ents<br />

will be built with <strong>on</strong>e or more sheets of plywood.<br />

If, say, you plan six 30" � 6' bunks and use a sheet for<br />

each, you’ll have six leftover pieces which are not<br />

particularly useful for anything else. Think of areas<br />

where they might fit and c<strong>on</strong>sider scarfing them into<br />

a larger piece. Ask yourself if any rounded partiti<strong>on</strong>s,<br />

bulkheads, shelves, or bunks can be cut out of rectangular<br />

stock. When you’ve finished this process, count<br />

up the number of full sheets you’ll need.<br />

All wood surfaces <strong>on</strong> your boat should be coated with<br />

<strong>WEST</strong> <strong>SYSTEM</strong> epoxy. Plan to apply at least two<br />

coatings—<strong>on</strong>e initial saturati<strong>on</strong> coat and <strong>on</strong>e buildup<br />

coat—to interiors and several more buildup coats to<br />

exterior surfaces. <strong>Epoxy</strong> will be used as an adhesive<br />

Applicati<strong>on</strong> Coverage ft2 /lb Coverage m2 /kg Waste Rate<br />

Initial saturati<strong>on</strong> coat 35 ft2 /lb 7.1 m2 /kg 20%<br />

Sec<strong>on</strong>dary buildup coat 40 ft 2 /lb 8.2 m 2 /kg 20%<br />

Interlaminate glue joint 13 ft 2 /lb 2.7 m 2 /kg 20%<br />

Fiberglass saturati<strong>on</strong> coat 12 oz/42 2 (400 g/m 2 ) 12 ft 2 /lb 2.5 m 2 /kg 10%<br />

Figure 7-3 Estimating <strong>WEST</strong> <strong>SYSTEM</strong> epoxy. A 105/205 or 206 Group B weighs 11 pounds. A 105/205 or 206 Group C weighs 50<br />

pounds. Refer to the current <strong>WEST</strong> <strong>SYSTEM</strong> price list to calculate the cost per pound and per square foot. C<strong>on</strong>tact the <str<strong>on</strong>g>Gouge<strong>on</strong></str<strong>on</strong>g><br />

technical staff to estimate alternate hardeners and sizes.