The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 26 – Interior C<strong>on</strong>structi<strong>on</strong> 319<br />

Figure 26-3 An IOR 1 ⁄2 t<strong>on</strong> racer. Bulkhead and partiti<strong>on</strong>s in<br />

the set-up are mixed with temporary particleboard molds.<br />

admit that there are some problems with installing<br />

interiors in inverted hulls—such as learning to measure<br />

upside down—but there are also many benefits.<br />

First, work can c<strong>on</strong>tinue <strong>on</strong> the exterior of the hull as<br />

you build the interior. This is particularly efficient if you<br />

have a large crew and are trying to finish the boat as<br />

quickly as possible. When you work <strong>on</strong> the floor, you<br />

have much more room than in an upright hull, so you<br />

can use more people and machinery. Some upright<br />

boats have <strong>on</strong>ly enough space for <strong>on</strong>e or two people.<br />

With these, working from the floor can allow two or<br />

three people to move around and also make room for<br />

machinery. Another benefit is that you can set up small<br />

benches and machinery such as a band saw, disc<br />

sander, and jointer inside the hull, and this saves labor.<br />

When the hull is inverted, you can save time by<br />

avoiding a lot of climbing. <str<strong>on</strong>g>The</str<strong>on</strong>g> average builder goes in<br />

and out of his hull several dozen times in the course of<br />

a day. With the hull upside down, you will <strong>on</strong>ly have to<br />

duck under the sheer. You can also raise it 2' (600mm)<br />

or more to make crawling in and out easier.<br />

Another advantage of building the interior while the<br />

hull is upside down is that work in progress is always<br />

much cleaner. Shavings and sawdust drop to the shop<br />

floor rather than into the bilge, so c<strong>on</strong>stant cleaning<br />

isn’t required. If you are building a boat with minimal<br />

shelter, an inverted hull can protect joinery, machinery,<br />

and stock from the elements.<br />

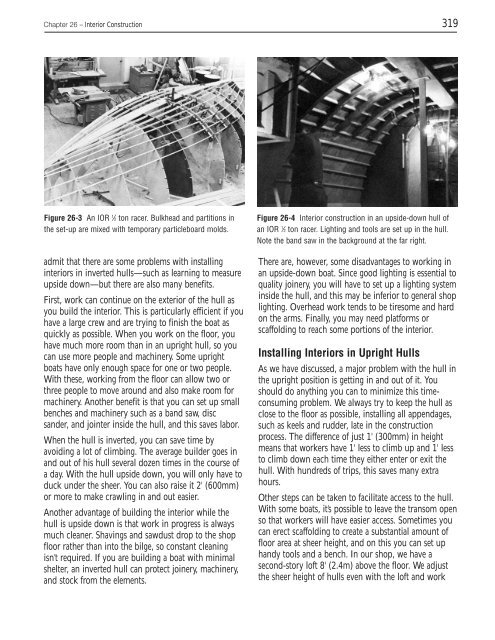

Figure 26-4 Interior c<strong>on</strong>structi<strong>on</strong> in an upside-down hull of<br />

an IOR 1 ⁄2 t<strong>on</strong> racer. Lighting and tools are set up in the hull.<br />

Note the band saw in the background at the far right.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are, however, some disadvantages to working in<br />

an upside-down boat. Since good lighting is essential to<br />

quality joinery, you will have to set up a lighting system<br />

inside the hull, and this may be inferior to general shop<br />

lighting. Overhead work tends to be tiresome and hard<br />

<strong>on</strong> the arms. Finally, you may need platforms or<br />

scaffolding to reach some porti<strong>on</strong>s of the interior.<br />

Installing Interiors in Upright Hulls<br />

As we have discussed, a major problem with the hull in<br />

the upright positi<strong>on</strong> is getting in and out of it. You<br />

should do anything you can to minimize this timec<strong>on</strong>suming<br />

problem. We always try to keep the hull as<br />

close to the floor as possible, installing all appendages,<br />

such as keels and rudder, late in the c<strong>on</strong>structi<strong>on</strong><br />

process. <str<strong>on</strong>g>The</str<strong>on</strong>g> difference of just 1' (300mm) in height<br />

means that workers have 1' less to climb up and 1' less<br />

to climb down each time they either enter or exit the<br />

hull. With hundreds of trips, this saves many extra<br />

hours.<br />

Other steps can be taken to facilitate access to the hull.<br />

With some boats, it’s possible to leave the transom open<br />

so that workers will have easier access. Sometimes you<br />

can erect scaffolding to create a substantial amount of<br />

floor area at sheer height, and <strong>on</strong> this you can set up<br />

handy tools and a bench. In our shop, we have a<br />

sec<strong>on</strong>d-story loft 8' (2.4m) above the floor. We adjust<br />

the sheer height of hulls even with the loft and work