The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

352 Later Producti<strong>on</strong> Steps<br />

Flat<br />

sawn<br />

stock<br />

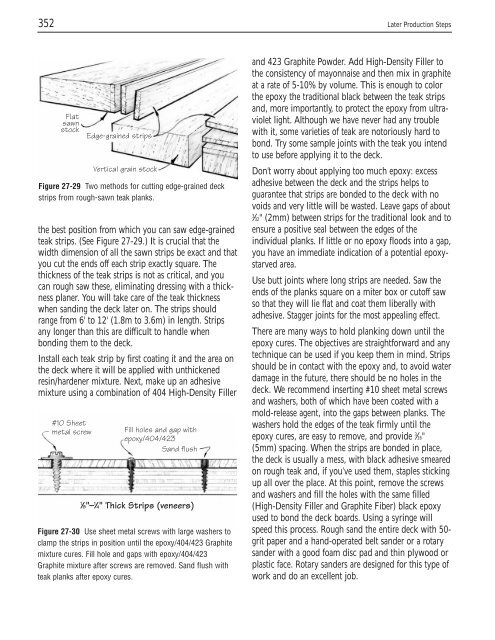

Figure 27-29 Two methods for cutting edge-grained deck<br />

strips from rough-sawn teak planks.<br />

the best positi<strong>on</strong> from which you can saw edge-grained<br />

teak strips. (See Figure 27-29.) It is crucial that the<br />

width dimensi<strong>on</strong> of all the sawn strips be exact and that<br />

you cut the ends off each strip exactly square. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

thickness of the teak strips is not as critical, and you<br />

can rough saw these, eliminating dressing with a thickness<br />

planer. You will take care of the teak thickness<br />

when sanding the deck later <strong>on</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g> strips should<br />

range from 6' to 12' (1.8m to 3.6m) in length. Strips<br />

any l<strong>on</strong>ger than this are difficult to handle when<br />

b<strong>on</strong>ding them to the deck.<br />

Install each teak strip by first coating it and the area <strong>on</strong><br />

the deck where it will be applied with unthickened<br />

resin/hardener mixture. Next, make up an adhesive<br />

mixture using a combinati<strong>on</strong> of 404 High-Density Filler<br />

#10 Sheet<br />

metal screw<br />

Edge-grained strips<br />

Vertical grain stock<br />

Fill holes and gap with<br />

epoxy/404/423<br />

Sand flush<br />

1 ⁄8"– 1 ⁄4" Thick Strips (veneers)<br />

Figure 27-30 Use sheet metal screws with large washers to<br />

clamp the strips in positi<strong>on</strong> until the epoxy/404/423 Graphite<br />

mixture cures. Fill hole and gaps with epoxy/404/423<br />

Graphite mixture after screws are removed. Sand flush with<br />

teak planks after epoxy cures.<br />

and 423 Graphite Powder. Add High-Density Filler to<br />

the c<strong>on</strong>sistency of may<strong>on</strong>naise and then mix in graphite<br />

at a rate of 5-10% by volume. This is enough to color<br />

the epoxy the traditi<strong>on</strong>al black between the teak strips<br />

and, more importantly, to protect the epoxy from ultraviolet<br />

light. Although we have never had any trouble<br />

with it, some varieties of teak are notoriously hard to<br />

b<strong>on</strong>d. Try some sample joints with the teak you intend<br />

to use before applying it to the deck.<br />

D<strong>on</strong>’t worry about applying too much epoxy: excess<br />

adhesive between the deck and the strips helps to<br />

guarantee that strips are b<strong>on</strong>ded to the deck with no<br />

voids and very little will be wasted. Leave gaps of about<br />

3<br />

⁄32" (2mm) between strips for the traditi<strong>on</strong>al look and to<br />

ensure a positive seal between the edges of the<br />

individual planks. If little or no epoxy floods into a gap,<br />

you have an immediate indicati<strong>on</strong> of a potential epoxystarved<br />

area.<br />

Use butt joints where l<strong>on</strong>g strips are needed. Saw the<br />

ends of the planks square <strong>on</strong> a miter box or cutoff saw<br />

so that they will lie flat and coat them liberally with<br />

adhesive. Stagger joints for the most appealing effect.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are many ways to hold planking down until the<br />

epoxy cures. <str<strong>on</strong>g>The</str<strong>on</strong>g> objectives are straightforward and any<br />

technique can be used if you keep them in mind. Strips<br />

should be in c<strong>on</strong>tact with the epoxy and, to avoid water<br />

damage in the future, there should be no holes in the<br />

deck. We recommend inserting #10 sheet metal screws<br />

and washers, both of which have been coated with a<br />

mold-release agent, into the gaps between planks. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

washers hold the edges of the teak firmly until the<br />

epoxy cures, are easy to remove, and provide 3 ⁄16"<br />

(5mm) spacing. When the strips are b<strong>on</strong>ded in place,<br />

the deck is usually a mess, with black adhesive smeared<br />

<strong>on</strong> rough teak and, if you’ve used them, staples sticking<br />

up all over the place. At this point, remove the screws<br />

and washers and fill the holes with the same filled<br />

(High-Density Filler and Graphite Fiber) black epoxy<br />

used to b<strong>on</strong>d the deck boards. Using a syringe will<br />

speed this process. Rough sand the entire deck with 50grit<br />

paper and a hand-operated belt sander or a rotary<br />

sander with a good foam disc pad and thin plywood or<br />

plastic face. Rotary sanders are designed for this type of<br />

work and do an excellent job.