The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

222 Hull C<strong>on</strong>structi<strong>on</strong> Methods<br />

set-up. Gaps between ribbands may be wider than the<br />

ribbands themselves so that <strong>on</strong>ly 40 or 50% of the<br />

mold surface is solid wood. Because staples can <strong>on</strong>ly<br />

be inserted where there are ribbands, we mark the first<br />

and sec<strong>on</strong>d layers of veneer before fastening them. This<br />

takes extra time, but since a ribband mold is quicker<br />

to build than a planked <strong>on</strong>e, the balance may lie in its<br />

favor when it will be used for <strong>on</strong>ly <strong>on</strong>e or two boats.<br />

Somewhere between these extremes lies the mold that<br />

is adequate for laminating most hulls. <str<strong>on</strong>g>The</str<strong>on</strong>g> quality of<br />

a mold is most important as the first two layers are<br />

laminated, when l<strong>on</strong>g staples are used to hold the<br />

veneers snug against it. Staples may be inserted<br />

anywhere in it, so a solid plug has a distinct advantage<br />

during this stage. One less elaborate way to build a<br />

str<strong>on</strong>g, rigid planked mold is to laminate two layers<br />

of 1 ⁄8" (3mm) veneer over an open, stringer mold.<br />

Producti<strong>on</strong> <strong>Boat</strong>building Molds<br />

Producti<strong>on</strong> boatbuilding molds come in two varieties<br />

comm<strong>on</strong>ly referred to as male and female molds. Male<br />

molds have c<strong>on</strong>vex surfaces and female molds have<br />

c<strong>on</strong>cave surfaces. Parts built <strong>on</strong> male molds are smooth<br />

<strong>on</strong> the inside surface (for example, a cockpit liner) and<br />

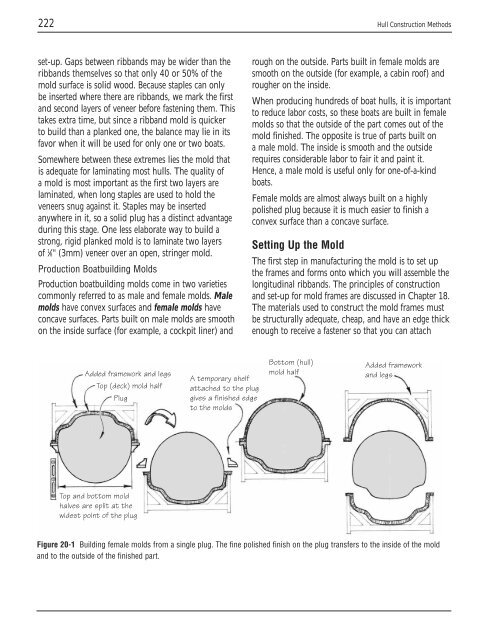

Added framework and legs<br />

Top (deck) mold half<br />

Plug<br />

Top and bottom mold<br />

halves are split at the<br />

widest point of the plug<br />

A temporary shelf<br />

attached to the plug<br />

gives a finished edge<br />

to the molds<br />

rough <strong>on</strong> the outside. Parts built in female molds are<br />

smooth <strong>on</strong> the outside (for example, a cabin roof) and<br />

rougher <strong>on</strong> the inside.<br />

When producing hundreds of boat hulls, it is important<br />

to reduce labor costs, so these boats are built in female<br />

molds so that the outside of the part comes out of the<br />

mold finished. <str<strong>on</strong>g>The</str<strong>on</strong>g> opposite is true of parts built <strong>on</strong><br />

a male mold. <str<strong>on</strong>g>The</str<strong>on</strong>g> inside is smooth and the outside<br />

requires c<strong>on</strong>siderable labor to fair it and paint it.<br />

Hence, a male mold is useful <strong>on</strong>ly for <strong>on</strong>e-of-a-kind<br />

boats.<br />

Female molds are almost always built <strong>on</strong> a highly<br />

polished plug because it is much easier to finish a<br />

c<strong>on</strong>vex surface than a c<strong>on</strong>cave surface.<br />

Setting Up the Mold<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> first step in manufacturing the mold is to set up<br />

the frames and forms <strong>on</strong>to which you will assemble the<br />

l<strong>on</strong>gitudinal ribbands. <str<strong>on</strong>g>The</str<strong>on</strong>g> principles of c<strong>on</strong>structi<strong>on</strong><br />

and set-up for mold frames are discussed in Chapter 18.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> materials used to c<strong>on</strong>struct the mold frames must<br />

be structurally adequate, cheap, and have an edge thick<br />

enough to receive a fastener so that you can attach<br />

Bottom (hull)<br />

mold half<br />

Added framework<br />

and legs<br />

Figure 20-1 Building female molds from a single plug. <str<strong>on</strong>g>The</str<strong>on</strong>g> fine polished finish <strong>on</strong> the plug transfers to the inside of the mold<br />

and to the outside of the finished part.