The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

The Gougeon Brothers on Boat Construction - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

146 Core <strong>Boat</strong>building Techniques<br />

have to worry so much about close tolerances as you<br />

drill. Increasing the diameter by 1 ⁄4" (6mm), for an<br />

annulus radius of 1 ⁄8" (3mm) makes the job of final<br />

fitting the hull and keel much easier.<br />

To drill the marked keel bolt holes, either use a drilling<br />

jig or ask a few friends to help you do it by eye. In<br />

either case, you need a drill which has a big motor and<br />

in which you can chuck a large bit. <str<strong>on</strong>g>The</str<strong>on</strong>g> drill bit should<br />

have a l<strong>on</strong>g shank: in some situati<strong>on</strong>s 20" to 30" (500-<br />

750 mm) is an ideal length range. If you can’t purchase<br />

drill bits that are l<strong>on</strong>g enough, have a machine shop<br />

weld a shank <strong>on</strong>to a standard bit.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> main goal of the drilling operati<strong>on</strong> is to make all<br />

of the keel bolt holes exactly parallel, matching the bolt<br />

arrangement <strong>on</strong> the keel. Although it takes some time<br />

to fabricate, a drilling jig produces maximum accuracy.<br />

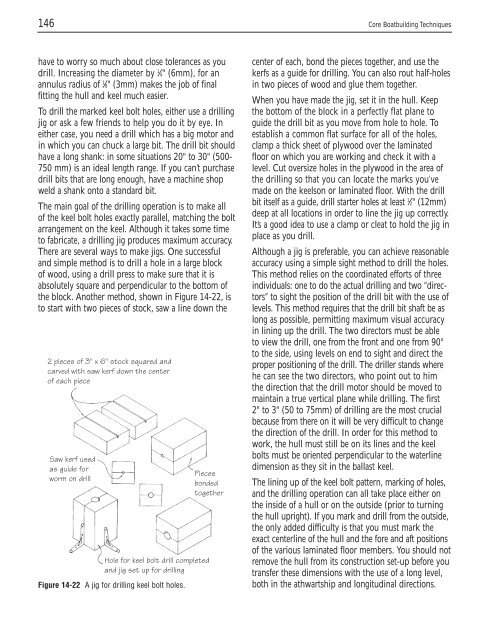

<str<strong>on</strong>g>The</str<strong>on</strong>g>re are several ways to make jigs. One successful<br />

and simple method is to drill a hole in a large block<br />

of wood, using a drill press to make sure that it is<br />

absolutely square and perpendicular to the bottom of<br />

the block. Another method, shown in Figure 14-22, is<br />

to start with two pieces of stock, saw a line down the<br />

2 pieces of 3" x 6" stock squared and<br />

carved with saw kerf down the center<br />

of each piece<br />

Saw kerf used<br />

as guide for<br />

worm <strong>on</strong> drill<br />

Figure 14-22 A jig for drilling keel bolt holes.<br />

Pieces<br />

b<strong>on</strong>ded<br />

together<br />

Hole for keel bolt drill completed<br />

and jig set up for drilling<br />

center of each, b<strong>on</strong>d the pieces together, and use the<br />

kerfs as a guide for drilling. You can also rout half-holes<br />

in two pieces of wood and glue them together.<br />

When you have made the jig, set it in the hull. Keep<br />

the bottom of the block in a perfectly flat plane to<br />

guide the drill bit as you move from hole to hole. To<br />

establish a comm<strong>on</strong> flat surface for all of the holes,<br />

clamp a thick sheet of plywood over the laminated<br />

floor <strong>on</strong> which you are working and check it with a<br />

level. Cut oversize holes in the plywood in the area of<br />

the drilling so that you can locate the marks you’ve<br />

made <strong>on</strong> the keels<strong>on</strong> or laminated floor. With the drill<br />

bit itself as a guide, drill starter holes at least 1 ⁄2" (12mm)<br />

deep at all locati<strong>on</strong>s in order to line the jig up correctly.<br />

It’s a good idea to use a clamp or cleat to hold the jig in<br />

place as you drill.<br />

Although a jig is preferable, you can achieve reas<strong>on</strong>able<br />

accuracy using a simple sight method to drill the holes.<br />

This method relies <strong>on</strong> the coordinated efforts of three<br />

individuals: <strong>on</strong>e to do the actual drilling and two “directors”<br />

to sight the positi<strong>on</strong> of the drill bit with the use of<br />

levels. This method requires that the drill bit shaft be as<br />

l<strong>on</strong>g as possible, permitting maximum visual accuracy<br />

in lining up the drill. <str<strong>on</strong>g>The</str<strong>on</strong>g> two directors must be able<br />

to view the drill, <strong>on</strong>e from the fr<strong>on</strong>t and <strong>on</strong>e from 90°<br />

to the side, using levels <strong>on</strong> end to sight and direct the<br />

proper positi<strong>on</strong>ing of the drill. <str<strong>on</strong>g>The</str<strong>on</strong>g> driller stands where<br />

he can see the two directors, who point out to him<br />

the directi<strong>on</strong> that the drill motor should be moved to<br />

maintain a true vertical plane while drilling. <str<strong>on</strong>g>The</str<strong>on</strong>g> first<br />

2" to 3" (50 to 75mm) of drilling are the most crucial<br />

because from there <strong>on</strong> it will be very difficult to change<br />

the directi<strong>on</strong> of the drill. In order for this method to<br />

work, the hull must still be <strong>on</strong> its lines and the keel<br />

bolts must be oriented perpendicular to the waterline<br />

dimensi<strong>on</strong> as they sit in the ballast keel.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> lining up of the keel bolt pattern, marking of holes,<br />

and the drilling operati<strong>on</strong> can all take place either <strong>on</strong><br />

the inside of a hull or <strong>on</strong> the outside (prior to turning<br />

the hull upright). If you mark and drill from the outside,<br />

the <strong>on</strong>ly added difficulty is that you must mark the<br />

exact centerline of the hull and the fore and aft positi<strong>on</strong>s<br />

of the various laminated floor members. You should not<br />

remove the hull from its c<strong>on</strong>structi<strong>on</strong> set-up before you<br />

transfer these dimensi<strong>on</strong>s with the use of a l<strong>on</strong>g level,<br />

both in the athwartship and l<strong>on</strong>gitudinal directi<strong>on</strong>s.