- Page 1:

AMOS MUMBA TARJA KETOLA (Eds) Respo

- Page 5 and 6:

Publisher Date of publication Vaasa

- Page 7 and 8:

CONTENTS Abstract in Finnish.......

- Page 9 and 10:

PART FIVE: CR MEASURES & STANDARDS

- Page 11 and 12:

PART ELEVEN: RESPONSIBLE LEADERSHIP

- Page 13 and 14:

PART ONE. COPORATE SUSTAINABILITY M

- Page 15 and 16:

Mr. Martin Clarke joined British Pr

- Page 17 and 18:

performances, e.g. cement productio

- Page 19 and 20:

“…identifying, managing and min

- Page 21 and 22:

The above list places emphasis acro

- Page 23 and 24:

Discussion: What Could Product Stew

- Page 25 and 26:

performance being awarded. Currentl

- Page 27 and 28:

CPA. 2007. Delivering sustainabilit

- Page 29 and 30:

Lewis. H. 2004. Defining product st

- Page 31 and 32:

ICRISAT - FROM A SUSTAINABLE POINT

- Page 33 and 34:

sorghum, pearl millet, chickpea, pi

- Page 35 and 36:

This action plan seems to produce g

- Page 37 and 38:

effects on nutrition and trace elem

- Page 39 and 40:

In figure two we can see the expend

- Page 41 and 42:

goods, but rather on insubstantial

- Page 43 and 44:

pressed to compete with an industri

- Page 45 and 46:

References CGIAR (2008). The Origin

- Page 47 and 48:

What is a Global Business Organizat

- Page 49 and 50:

The majority of the above seven cri

- Page 51 and 52:

38 3 Limited statement NAM 75 NAM /

- Page 53 and 54:

40 Statement 4 Limited Statement NA

- Page 55 and 56:

equirements, but at the same time b

- Page 57 and 58:

transition from EMS to SMS can be a

- Page 59 and 60:

adequate as an SMS in a GBO. Furthe

- Page 61 and 62:

48 Table 2: Detailed Description of

- Page 63 and 64:

50 substitution is recognized, but

- Page 65 and 66:

52 acted on Improvement Process Usi

- Page 67 and 68:

54 Boundary & interface between SMS

- Page 69 and 70:

56 System Component #6 - Value Chai

- Page 71 and 72:

58 requirements implemented actions

- Page 73 and 74:

Global Reporting Initiative (2006).

- Page 75 and 76:

van Tulder, R., van den Berghe, D.,

- Page 77 and 78:

esponsibilities to stakeholders and

- Page 79 and 80:

develop improvement and learning sy

- Page 81 and 82:

easonably well now and making them

- Page 83 and 84:

Responsible competitiveness The que

- Page 85 and 86:

examples? What are the main commitm

- Page 87 and 88:

Responsibility to users of products

- Page 89 and 90:

of independent research institutes

- Page 91 and 92:

development that capture and estima

- Page 93 and 94:

Hooghe L, Marks G. (2003). Unraveli

- Page 95 and 96:

Waddock, S. and Bodwell C. (2007).

- Page 97 and 98:

THE INTEGRATION OF CSR INTO BUSINES

- Page 99 and 100:

Theoretical Background Strategic CS

- Page 101 and 102:

against specific requirements. The

- Page 103 and 104:

industries (energy, utilities, oil

- Page 105 and 106:

Different Approaches to CSR The two

- Page 107 and 108:

• Electromagnetism and impact on

- Page 109 and 110:

Conclusions In the first stage of t

- Page 111 and 112:

Appendix A Level of integration of

- Page 113 and 114:

99 High Independent BU/Committee de

- Page 115 and 116:

101 McAdam, R. & Leonard, D. (2003)

- Page 117 and 118:

ECONOMIC DOWNTURN AND THE LANGUAGE

- Page 119 and 120:

105 Additionally, for Foucault, and

- Page 121 and 122:

Approach 107 The discussion in this

- Page 123 and 124:

need for firms to tighten their bel

- Page 125 and 126:

esult of economic-market system; th

- Page 127 and 128:

Resource Allocation and the Home of

- Page 129 and 130: 115 Such divergent views raise ques

- Page 131 and 132: References Accountancy Age (2009) C

- Page 133 and 134: IMAGE DIFFERENCIATION WITH CORPORAT

- Page 135 and 136: 121 argues that industries with a c

- Page 137 and 138: 123 Since not all stakeholders valu

- Page 139 and 140: Empirical Findings The first propos

- Page 141 and 142: 127 The right amount of CR is when

- Page 143 and 144: Environmentally Responsible Image D

- Page 145 and 146: corporate responsibility can be a m

- Page 147 and 148: References Ansoff, H. I. & McDonnel

- Page 149 and 150: Miller, D. (1992). The Generic Stra

- Page 151 and 152: SEED INDUSTRY RESPONSIBILITY TO AGR

- Page 153 and 154: 139 intellectual property protectio

- Page 155 and 156: 141 Thus, they stress their donatio

- Page 157 and 158: Social Issues 143 Regarding the soc

- Page 159 and 160: 145 food system which in their opin

- Page 161 and 162: DuPont (2002). Science, Solutions a

- Page 163 and 164: IgNN (2008c). Brüssel will bessere

- Page 165 and 166: A VALUE CHAIN ANALYSIS OF THE ORGAN

- Page 167 and 168: 153 friendly ranges setting a trend

- Page 169 and 170: The Main Factors Affecting The Grow

- Page 171 and 172: 157 Governments, particularly in Eu

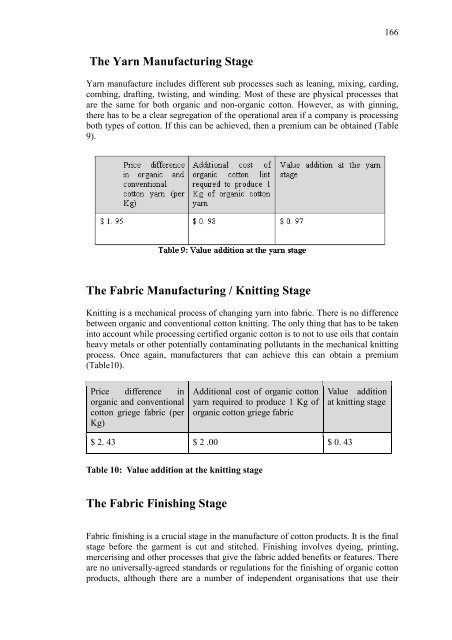

- Page 173 and 174: Table 4: Value addition at each sta

- Page 175 and 176: organic cotton farms typically achi

- Page 177 and 178: 163 Cumulative value loss/ addition

- Page 179: 165

- Page 183 and 184: Price difference in organic and con

- Page 185 and 186: References 171 Alfoeldi, T., Fließ

- Page 187 and 188: 173 Fliessbach, A. and Mäder, P. (

- Page 189 and 190: 175 Sinden, J. A., Griffith, G. (20

- Page 191 and 192: INSTITUTIONALISING IDEALISM: PATTER

- Page 193 and 194: 179 Social considerations include i

- Page 195 and 196: Coercive Adoption 181 The second st

- Page 197 and 198: of non-adopters; the moral content

- Page 199 and 200: References Ackerman, R. (1973). How

- Page 201 and 202: Economist. (2008). The next questio

- Page 203 and 204: Porter, M., & Kramer, M. (2002). Th

- Page 205 and 206: CULTURAL CONTEXT OF CSR: COMPARATIV

- Page 207 and 208: 193 power is distributed unequally.

- Page 209 and 210: 195 Figure 1: Values Associated wit

- Page 211 and 212: 197 answering the questions. Most D

- Page 213 and 214: Culture in Nation-Institutions 199

- Page 215 and 216: 201 In line with the collectivistic

- Page 217 and 218: Stakeholders 203 From the field-lev

- Page 219 and 220: Codes & Policies Volunteering Phila

- Page 221 and 222: 207 The wealth capacity-building in

- Page 223 and 224: Hannigan, J. A. (2006). Social cons

- Page 225 and 226: 211 Thelen, K. & Steinmo, S. (1992)

- Page 227 and 228: 213 Historically, Danish companies

- Page 229 and 230: 215 survey was carried out by email

- Page 231 and 232:

217 role, especially in the 1990s,

- Page 233 and 234:

when CSR policies in Denmark were m

- Page 235 and 236:

221 The business areas of the Danfo

- Page 237 and 238:

223 While looking at the CSR Waves,

- Page 239 and 240:

225 marital affairs and on financia

- Page 241 and 242:

whether Danfoss is considered good

- Page 243 and 244:

229 the making of Danfoss’ Ethics

- Page 245 and 246:

have, from participating in interna

- Page 247 and 248:

Global Reporting Initiative. G3 Gui

- Page 249 and 250:

Negative List for Substances and Ma

- Page 251 and 252:

237 and three. In both approaches k

- Page 253 and 254:

239 protection/environmental enhanc

- Page 255 and 256:

241 sufficiently informed only by b

- Page 257 and 258:

Table 3: Traditional versus sophist

- Page 259 and 260:

• Dialogue needs to go beyond dis

- Page 261 and 262:

and needs of CSR-for-SD as outlined

- Page 263 and 264:

• evaluations are externally faci

- Page 265 and 266:

251 • Values and cultural factors

- Page 267 and 268:

References 253 ACCA The Association

- Page 269 and 270:

Freeman, R.E. 1984. Strategic Manag

- Page 271 and 272:

257 Pretty, J., Shah, P. 1994. Soil

- Page 273 and 274:

PART THREE: CORPORATE RESPONSIBILIT

- Page 275 and 276:

261 business houses should follow t

- Page 277 and 278:

263 One other problem faced in Indi

- Page 279 and 280:

CORPORATE SOCIAL RESPONSIBILITY INI

- Page 281 and 282:

267 In spite of the increasing impo

- Page 283 and 284:

269 value, while either protecting

- Page 285 and 286:

identify the main trends of the CSR

- Page 287 and 288:

OIL AND GAS COMPANIES Table 1. CSR

- Page 289 and 290:

ENI EXXON PETROBRAS Evaluation of l

- Page 291 and 292:

TOTAL Promotion of several initiati

- Page 293 and 294:

e. Lack of Human Resources 279 The

- Page 295 and 296:

References Bevacqua, S. & Cascinai,

- Page 297 and 298:

PART FOUR: CORPORATE RESPONSIBILITY

- Page 299 and 300:

285 During the past decades, litera

- Page 301 and 302:

287 research involved three Tuscan

- Page 303 and 304:

289 • in terms of preferences on

- Page 305 and 306:

291 followed by lack of resources a

- Page 307 and 308:

293 health and safety of the worker

- Page 309 and 310:

References Adler, P. and S.-W. Kwon

- Page 311 and 312:

297 Russo A. and Tencati A. 2009, F

- Page 313 and 314:

299 by companies in order to contri

- Page 315 and 316:

301 economic growth it does not con

- Page 317 and 318:

Anttonen (2008) has divided chemica

- Page 319 and 320:

305 different types of consultative

- Page 321 and 322:

Picture 2. The BASF business model

- Page 323 and 324:

309 compounds are used in all indus

- Page 325 and 326:

311 Halme, M., Anttonen, M., Kuisma

- Page 327 and 328:

DOES OPEN INNOVATION STREGHTHEN COR

- Page 329 and 330:

Sustainable Change and CR 315 Due t

- Page 331 and 332:

317 OIM are all methods that open t

- Page 333 and 334:

319 expressive than an instrumental

- Page 335 and 336:

Results 321 It is new to accept and

- Page 337 and 338:

on process User mainly need- and kn

- Page 339 and 340:

325 interaction enables companies t

- Page 341 and 342:

References Alvesson, M. (2005). Und

- Page 343 and 344:

329 Hübscher, M. & Müller, M. (20

- Page 345 and 346:

Walcher, D. (2007). Der Ideenwettbe

- Page 347 and 348:

333 The current context in which or

- Page 349 and 350:

335 existence and are able to survi

- Page 351 and 352:

337 particular the political and le

- Page 353 and 354:

339 local variants emerged in Scand

- Page 355 and 356:

341 However, these output oriented

- Page 357 and 358:

Regarding the activity S2 ‘Stakeh

- Page 359 and 360:

References Achterbergh, J., Vriens,

- Page 361 and 362:

Nieuwkamp, B.E.M. (2008). De arbeid

- Page 363 and 364:

FINANCIAL VALUE MEASUREMENT OF CORP

- Page 365 and 366:

351 responsibility issues (roadmap)

- Page 367 and 368:

353 financial valuation measures. T

- Page 369 and 370:

Table 1. Features in the various ph

- Page 371 and 372:

sustainability data gathering and i

- Page 373 and 374:

Table 3. Sustainability-related GRI

- Page 375 and 376:

Three Illustrations of Deriving and

- Page 377 and 378:

363 where it uses renewable resourc

- Page 379 and 380:

References Adams, C. A. (2004). The

- Page 381 and 382:

367 Niskala, M., & Schadewitz, H. (

- Page 383 and 384:

Huhtamäki (Materials) Kemira (Mate

- Page 385 and 386:

OKO (Finance) organization with who

- Page 387 and 388:

373 [1] Global Reporting Initiative

- Page 389 and 390:

Introduction 375 The concepts relat

- Page 391 and 392:

Model Foundations First foundation

- Page 393 and 394:

As we can see in the Figure 2, on t

- Page 395 and 396:

381 model in subject. Through these

- Page 397 and 398:

383 For Schwartz and Bilsky (SCHWAR

- Page 399 and 400:

385 • Reaction: The organization

- Page 401 and 402:

Figure 7: Tripod of the sustainabil

- Page 403 and 404:

389 The second fundament of the mod

- Page 405 and 406:

Figure 10: Organizational Social Pe

- Page 407 and 408:

Figure 13: Wilber’s Model Source:

- Page 409 and 410:

Figure 15: Model of sustainable exc

- Page 411 and 412:

Figure 17: Proposal of model evalua

- Page 413 and 414:

399 Figure 19: Relationships took i

- Page 415 and 416:

Jung, C. F. (2003). Metodologia Cie

- Page 417 and 418:

Werre, Marco. & Marcel. Van Marrewi

- Page 419 and 420:

THE CASE OF SOCIAL ENTERPRISES: ARE

- Page 421 and 422:

407 The present paper aims to revie

- Page 423 and 424:

Belgium Law of 13 April 1995 United

- Page 425 and 426:

Social Enteprise: Some Definitions

- Page 427 and 428:

The Social Entrepreneurship Accordi

- Page 429 and 430:

Figure 1 The blurring sectoral boun

- Page 431 and 432:

f) An initiative launched by a grou

- Page 433 and 434:

References Alter, S.K. (2004) Socia

- Page 435 and 436:

A DISCOURSE ANALYSIS OF THE FAIRTRA

- Page 437 and 438:

423 constituting the social (Faircl

- Page 439 and 440:

425 Once economic behaviour is no l

- Page 441 and 442:

427 link to Fairtrade, in which Fai

- Page 443 and 444:

France: Producers and Competition 4

- Page 445 and 446:

UK: Producers and Competition 431 W

- Page 447 and 448:

that for Fairtrade to work it has t

- Page 449 and 450:

436 01/01/2007 01/01/2007 01/01/200

- Page 451 and 452:

438 01/01/2003 01/01/2003 01/01/200

- Page 453 and 454:

440 Jaworski, A. & Coupland, N. (19

- Page 455 and 456:

PART SEVEN: PUBLIC - PRIVATE PARTNE

- Page 457 and 458:

444 It also examines the applicabil

- Page 459 and 460:

446 critical resources controlled b

- Page 461 and 462:

448 In October 2008, NVPC launched

- Page 463 and 464:

S$1 policy but perhaps other more i

- Page 465 and 466:

References Azlan A, Lim LL, Yahya S

- Page 467 and 468:

PART EIGHT: CORPORATE RESPONSIBILIT

- Page 469 and 470:

organizations, with different aims

- Page 471 and 472:

458 Decentralization and local gove

- Page 473 and 474:

460 When multiple actors involved i

- Page 475 and 476:

462 Governance, economy, social cap

- Page 477 and 478:

464 In this sense, analysing a terr

- Page 479 and 480:

Partnerships Social Capital 466 - S

- Page 481 and 482:

468 The level of civic participatio

- Page 483 and 484:

Conclusion - Quality of the environ

- Page 485 and 486:

Garvin, T. et al. (2009). Community

- Page 487 and 488:

THE EFFECTS OF “DEPENDENCY” ON

- Page 489 and 490:

how, this dependence inhibits effec

- Page 491 and 492:

478 the MNC effectively. This secti

- Page 493 and 494:

480 regulation via CSR policy, whic

- Page 495 and 496:

482 potential consumer base in each

- Page 497 and 498:

References 484 An Roinn Gnóthaí P

- Page 499 and 500:

Lambe. A., Directors' Compliance St

- Page 501 and 502:

INVESTIGATING THE PRINCIPLES OF COR

- Page 503 and 504:

490 economic and institutional deve

- Page 505 and 506:

492 and corporate governance. The w

- Page 507 and 508:

494 corporate stakeholders, of weal

- Page 509 and 510:

496 failures by corporate boards to

- Page 511 and 512:

498 fashion", therefore I intend to

- Page 513 and 514:

ENVIRONMENTAL MANAGEMENT PRACTICES

- Page 515 and 516:

An Overview of Environmental Manage

- Page 517 and 518:

Feichtinger and Pregernig, 2005; Gr

- Page 519 and 520:

Survey Questionnaire 506 The raw da

- Page 521 and 522:

Table 4. Variables used to compute

- Page 523 and 524:

inhabitants and workers) and the ex

- Page 525 and 526:

512 particular purchase, the incent

- Page 527 and 528:

514 which limits the adoption of be

- Page 529 and 530:

Conclusions 516 The overall profile

- Page 531 and 532:

Cuthill, M. (2002). Exploratory res

- Page 533 and 534:

520 Lundberg, K., Balforsa, B. and

- Page 535 and 536:

RELATIONAL GOVERNANCE AND THE DEVEL

- Page 537 and 538:

524 national-level plans to constru

- Page 539 and 540:

Relational Governance 526 One of th

- Page 541 and 542:

Case Studies: Vankorneft and the Ev

- Page 543 and 544:

The shape of Russian public CSR pol

- Page 545 and 546:

Report on CSR in the forestry indus

- Page 547 and 548:

534 At the Turukhansk district leve

- Page 549 and 550:

536 Russian federal legislature vio

- Page 551 and 552:

538 The maintenance of the long-ter

- Page 553 and 554:

References 540 Albareda, L., Lozano

- Page 555 and 556:

542 Moon, J. (2004). Government as

- Page 557 and 558:

PART NINE: RENEWABLE ENERGY 544

- Page 559 and 560:

546 generating the various form of

- Page 561 and 562:

• The lack of basic infrastructur

- Page 563 and 564:

550 − A Tool for assessing the ec

- Page 565 and 566:

ARTICULATION OF ENVIRONMENTAL AND S

- Page 567 and 568:

- Cramer Commission56, - Renewable

- Page 569 and 570:

556 conditions + + + + + + + + Prop

- Page 571 and 572:

Figure 1 - Impacts of direct and in

- Page 573 and 574:

Figure 3 - Impacts of direct and in

- Page 575 and 576:

Figure 6 - Impacts of agricultural

- Page 577 and 578:

Agricultural practices have also im

- Page 579 and 580:

566 Nevertheless, land-use changes

- Page 581 and 582:

- Discussion possibilities, - Free

- Page 583 and 584:

References ACCS (2007a). AFS Standa

- Page 585 and 586:

Renewable Fuels Agency (2008), The

- Page 587 and 588:

Abstract SUPPLY CHAIN ISSUES OF BIO

- Page 589 and 590:

576 adjusted to the specific condit

- Page 591 and 592:

energy and logistics/SCM. Follow-up

- Page 593 and 594:

Madlener & Bachhiesl 2007 Perry & R

- Page 595 and 596:

Elghali et al. 2007 Madlener & Bach

- Page 597 and 598:

584 on the other hand state that a

- Page 599 and 600:

586 expeller, olive cake and wood p

- Page 601 and 602:

588 torrefaction and pelletisation

- Page 603 and 604:

Berglund, M. (2006). Biogas product

- Page 605 and 606:

SUSTAINABILITY CYCLE ASSESMENT OF B

- Page 607 and 608:

Figure 1. Cradle-to-grave grave app

- Page 609 and 610:

Table 1. Environmental, social cult

- Page 611 and 612:

Table 2. Environmental, social cult

- Page 613 and 614:

600 In summary, while biodiesel is

- Page 615 and 616:

602 nature after use: when the soli

- Page 617 and 618:

604 the creation, refinement, use a

- Page 619 and 620:

Test Results 606 Biogases are envir

- Page 621 and 622:

ID=78&articleID=1163 608 WCED (1987

- Page 623 and 624:

610 business of sustainability and

- Page 625 and 626:

Table 2. The Equator Principles and

- Page 627 and 628:

614 Strategic orientation of firms

- Page 629 and 630:

616 Natural gas fuels over 99 perce

- Page 631 and 632:

618 building a Hydrogen Energy plan

- Page 633 and 634:

620 principles that are related to

- Page 635 and 636:

Impact on Climate Change Conclusion

- Page 637 and 638:

Falck, O. & Heblich, S. Corporate s

- Page 639 and 640:

ROBIN HOOD THEOREM: A WAY FOR ENERG

- Page 641 and 642:

628 communities have to contend and

- Page 643 and 644:

630 to power basic devices like TV

- Page 645 and 646:

References Abavana, G. C, (2004). G

- Page 647 and 648:

INTRA-INDUSTRY IMITATION IN ENVIRON

- Page 649 and 650:

636 The legislation has also contri

- Page 651 and 652:

In general, the larger the organisa

- Page 653 and 654:

Content Analysis 640 In order to be

- Page 655 and 656:

642 One of the key questions in ass

- Page 657 and 658:

Table 4. Stakeholder considered by

- Page 659 and 660:

646 Table 5. GRI indicators accordi

- Page 661 and 662:

Refferences Adams, C.A. (2004). The

- Page 663 and 664:

Gray, R. (2006). Does Sustainabilit

- Page 665 and 666:

SUPPLY CHAIN CORPORATE RESPONSIBILI

- Page 667 and 668:

654 The sample was selected from th

- Page 669 and 670:

Table 2 Survey Categories used to E

- Page 671 and 672:

y reading the relevant sections. Th

- Page 673 and 674:

660 Perhaps not surprisingly compan

- Page 675 and 676:

662 Only 3 companies reported the e

- Page 677 and 678:

iodiversity (IPES, 2008). The IPES

- Page 679 and 680:

usiness level playing field and, wh

- Page 681 and 682:

668 EICC. (2006). Electronic Indust

- Page 683 and 684:

PART ELEVEN: RESPONSIBLE LEADERSHIP

- Page 685 and 686:

Value Basis 672 Finding one’s tru

- Page 687 and 688:

674 The lure of quick profits, stat

- Page 689 and 690:

676 politics he talked and wrote ab

- Page 691 and 692:

The Responsible Leadership Identiti

- Page 693 and 694:

villages of Bangladesh. He set up a

- Page 695 and 696:

States: Building Blocks of Some Res

- Page 697 and 698:

Conclusions Matching Individual, Or

- Page 699 and 700:

686 The different characteristics o

- Page 701 and 702:

Issue: Corporate Responsibility & D

- Page 703 and 704:

690 society at large”. Other defi

- Page 705 and 706:

Table 1. Reasons for implementing e

- Page 707 and 708:

694 environment and develop a bette

- Page 709 and 710:

696 Does this imply that corporate

- Page 711 and 712:

and certifying environmental manage

- Page 713 and 714:

Perspective from law, economics, an

- Page 715 and 716:

702 However neither Japan nor Germa

- Page 717 and 718:

704 community pressure, and environ

- Page 719 and 720:

706 international competitiveness (

- Page 721 and 722:

708 and Alberini 2002). The functio

- Page 723 and 724:

Public Politics and Private Politic

- Page 725 and 726:

these three actors have been strong

- Page 727 and 728:

714 Imura, H. (2005). Japan's Envir

- Page 729 and 730:

716 technical aspects of environmen

- Page 731 and 732:

718 However, a more in-depth discus

- Page 733 and 734:

720 empirically tested in a number

- Page 735 and 736:

722 the level of awareness and envi

- Page 737 and 738:

724 solutions might even exaggerate

- Page 739 and 740:

References Albrecht, D., Bultena, G

- Page 741 and 742:

728 Klein, K. J. & Kozlowski, S. W.

- Page 743 and 744:

PART TWELVE: SMEs & CORPORATE RESPO

- Page 745 and 746:

732 SMEs, Training and Sustainabili

- Page 747 and 748:

734 The values of an SME are predom

- Page 749 and 750:

SMEs, but these have rarely lived u

- Page 751 and 752:

738 believe that this course of act

- Page 753 and 754:

(Revell and Rutherfoord, 2003). The

- Page 755 and 756:

Diagram 2: Conceptual Framework - F

- Page 757 and 758:

Reference 744 Ammenberg, J. and Hje

- Page 759 and 760:

746 Hall, G, 1989). Lack of Finance

- Page 761 and 762:

748 Sheridan, P., (2001). Directors

- Page 763 and 764:

750 theories focus on the transfera

- Page 765 and 766:

752 traditional models of managemen

- Page 767 and 768:

end of the fifth year of life marks

- Page 769 and 770:

Figure 1 The model The Research The

- Page 771 and 772:

The Area Selected and the Ccow Buff

- Page 773 and 774:

760 The Plan must guarantee the att

- Page 775 and 776:

Managerial Implications, Limits of

- Page 777 and 778:

Freeman R.E. (1984). Strategic Mana

- Page 779 and 780:

CSR-TOOLS FOR SMEs - COMPARATIVE AN

- Page 781 and 782:

Features of CSR in SMEs 768 CSR was

- Page 783 and 784:

770 mostly provide overviews and in

- Page 785 and 786:

772 The CSR Quality Seal is essenti

- Page 787 and 788:

774 into its strategic as well as o

- Page 789 and 790:

Outcome and Conclusions 776 BLISS w

- Page 791 and 792:

References Bhuiyan, N. & Bagehel, A

- Page 793 and 794:

780 Honen, P. & Potts, J. (2007). C

- Page 795 and 796:

782 SUPPLY - CHAIN ENVIRONMENTAL MA

- Page 797 and 798:

784 offers a useful discussion and

- Page 799 and 800:

786 22’ noted by Fanshawe (2000)

- Page 801 and 802:

788 action) and the sense made of t

- Page 803 and 804:

790 The latter provided clear benef

- Page 805 and 806:

792 Figure 3 - Describing the Behav

- Page 807 and 808:

794 Interestingly though, and despi

- Page 809 and 810:

Summary and Comment 796 In the earl

- Page 811 and 812:

de Wit, B. and Meyer, R. (1999). St

- Page 813 and 814:

Remenyi, D., Williams, B., Money, A

- Page 815 and 816:

FACTORS AFFECTING THE ENGAGING IN C

- Page 817 and 818:

804 this issue can be examined with

- Page 819 and 820:

Table 1 List of factors affecting f

- Page 821 and 822:

voluntariness” proposed by Moore

- Page 823 and 824:

Table 2: The state of CSR practices

- Page 825 and 826:

Table 3 Factor analysis: variables

- Page 827 and 828:

814 However, there are also challen

- Page 829 and 830:

Grayson, D. (2004). How CSR Contrib

- Page 831 and 832:

Spence, L. J. , & Rutherfoord, R. (

- Page 833 and 834:

820 This paper draws on both primar

- Page 835 and 836:

Case Studies 822 The case studies e

- Page 837 and 838:

Rationale and Start up 824 In this

- Page 839 and 840:

826 own standards, and those of her

- Page 841 and 842:

828 Finally all three of these case

- Page 843 and 844:

References Journal Articles 830 Goo

- Page 845 and 846:

CORPORATE RESPONSIBILITY: A CRICIAL

- Page 847 and 848:

834 The most visible parts of the c

- Page 849 and 850:

Accordingly, referring to Basu and

- Page 851 and 852:

measures on the other hand show hug

- Page 853 and 854:

policies are accompanied by company

- Page 855 and 856:

Conclusion 842 The described percep

- Page 857 and 858:

Eckert, S. et al. (2007). Nachhalti

- Page 859 and 860:

Nielsen, A.E. & Thomsen, C. (2009)

- Page 861 and 862:

PART THIRTEEN: CONSUMERS AND ETHICS

- Page 863 and 864:

850 (www.fairtrade.net). Different

- Page 865 and 866:

852 Organizations International) an

- Page 867 and 868:

854 The first step of the research

- Page 869 and 870:

Table 1- Knowledge measurement stat

- Page 871 and 872:

• Quality aspect: quality of the

- Page 873 and 874:

References Blowfield, Mick. (2003).

- Page 875 and 876:

GAMBLING, SMOKING AND DRINKING: WHA

- Page 877 and 878:

864 assistance was given by license

- Page 879 and 880:

261) suggested that they had some i

- Page 881 and 882:

868 or banned altogether. Only one

- Page 883 and 884:

Lantos, G.P. (1999). ‘Motivating