Bravo & Brava • 1995 To 2000

Bravo & Brava • 1995 To 2000

Bravo & Brava • 1995 To 2000

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2E»16 Engine removal and overhaul procedures<br />

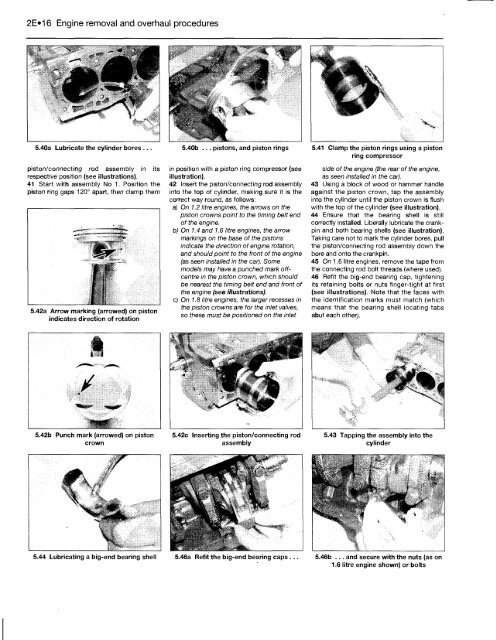

5.40a Lubricate the cylinder bores ...<br />

piston/connecting rod assembly in its<br />

respective position (see illustrations).<br />

41 Start with assembly No 1. Position the<br />

piston ring gaps 120° apart, then clamp them<br />

5.42a Arrow marking (arrowed) on piston<br />

indicates direction of rotation<br />

5.42b Punch mark (arrowed) on piston<br />

crown<br />

5.44 Lubricating a big-end bearing shell<br />

5.40b ... pistons, and piston rings<br />

in position with a piston ring compressor (see<br />

illustration).<br />

42 Insert the piston/connecting rod assembly<br />

into the top of cylinder, making sure it is the<br />

correct way round, as follows:<br />

a) On 1.2 litre engines, the arrows on the<br />

piston crowns point to the timing belt end<br />

of the engine.<br />

b) On 1.4 and 1.6 litre engines, the arrow<br />

markings on the base of the pistons<br />

indicate the direction of engine rotation,<br />

and should point to the front of the engine<br />

(as seen installed in the car). Some<br />

models may have a punched mark offcentre<br />

in the piston crown, which should<br />

be nearest the timing belt end and front of<br />

the engine (see illustrations).<br />

c) On 1.8 litre engines, the larger recesses in<br />

the piston crowns are for the inlet valves,<br />

so these must be positioned on the inlet<br />

5.42c Inserting the piston/connecting rod<br />

assembly<br />

5.46a Refit the big-end bearing caps ...<br />

5.41 Clamp the piston rings using a piston<br />

ring compressor<br />

side of the engine (the rear of the engine,<br />

as seen installed in the car).<br />

43 Using a block of wood or hammer handle<br />

against the piston crown, tap the assembly<br />

into the cylinder until the piston crown is flush<br />

with the top of the cylinder (see illustration).<br />

44 Ensure that the bearing shell is still<br />

correctly installed. Liberally lubricate the crankpin<br />

and both bearing shells (see illustration).<br />

Taking care not to mark the cylinder bores, pull<br />

the piston/connecting rod assembly down the<br />

bore and onto the crankpin.<br />

45 On 1.6 litre engines, remove the tape from<br />

the connecting rod bolt threads (where used).<br />

46 Refit the big-end bearing cap, tightening<br />

its retaining bolts or nuts finger-tight at first<br />

(see illustrations). Note that the faces with<br />

the identification marks must match (which<br />

means that the bearing shell locating tabs<br />

abut each other).<br />

5.43 Tapping the assembly into the<br />

cylinder<br />

5.46b ... and secure with the nuts (as on<br />

1.6 litre engine shown) or bolts