- Page 1 and 2:

Public Disclosure Authorized Public

- Page 3 and 4:

EXECUTIVE SUMMARY INTRODUCTION Azur

- Page 5 and 6:

• Screening and scoping • Basel

- Page 7 and 8:

In addition to predicted impacts fr

- Page 9 and 10:

International Standards and Guideli

- Page 11 and 12:

Figure 1 Layout of Proposed Power P

- Page 13 and 14:

Type of Emission Solid waste All so

- Page 15 and 16:

NIPP were used for NO 2. The result

- Page 17 and 18:

analysis are both qualitative and q

- Page 19 and 20:

other forms of salary jobs or servi

- Page 21 and 22:

Table 4 Summary of Impacts, Mitigat

- Page 23 and 24:

Impact Impact Description Phase Pre

- Page 25 and 26:

Impact Impact Description Phase Pre

- Page 27 and 28:

Impact Impact Description Phase Pre

- Page 29 and 30:

Impact Impact Description Phase Pre

- Page 31 and 32:

Impact Impact Description Phase Pre

- Page 33 and 34:

Box 2 Mitigation Hierarchy for Plan

- Page 35 and 36:

safety impacts are reduced to minor

- Page 37 and 38: 5.2 METHODOLOGY 5-2 5.3 DEMOGRAPHIC

- Page 39 and 40: Annex G - Unplanned Events and Emer

- Page 41 and 42: IAEA International Atomic Energy Ag

- Page 43 and 44: 1 INTRODUCTION 1.1 BACKGROUND This

- Page 45 and 46: 1.2.2 Project Context The Project w

- Page 47 and 48: Table 1.1 The EIA Team Name Organis

- Page 49 and 50: EIA, sampling has been completed fo

- Page 51 and 52: events is therefore assessed in ter

- Page 53 and 54: Federal Ministry of Environment Pri

- Page 55 and 56: Edo State Waste Management Board Th

- Page 57 and 58: The proposed Project requires an EI

- Page 59 and 60: as a building or irrigation system)

- Page 61 and 62: instrument for monitoring and contr

- Page 63 and 64: Convention Concerning the Protectio

- Page 65 and 66: Box 1.2 World Bank Safeguard Polici

- Page 67 and 68: • Step 5. Stakeholder Consultatio

- Page 69 and 70: Chapter Title Description 8 Mitigat

- Page 71 and 72: commensurate sums that will need to

- Page 73 and 74: operation of the Project. The imple

- Page 75 and 76: 2.4.3 Social Sustainability A detai

- Page 77 and 78: signing of a Memorandum of Understa

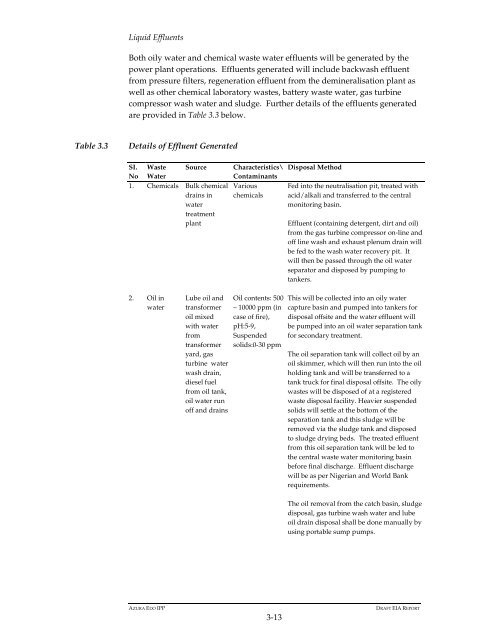

- Page 79 and 80: Key Component OCGT Associated Machi

- Page 81 and 82: Gas Turbine Building The four gas t

- Page 83 and 84: Government parastatal that has been

- Page 85 and 86: 3.2.10 Fire Protection The gas turb

- Page 87: foundations and is associated with

- Page 91 and 92: 3.3.4 Administration Buildings The

- Page 93 and 94: the area reserved for the HRSG and

- Page 95 and 96: 3.6 OPERATION 3.6.1 Maintenance It

- Page 97 and 98: Job title Level of Skill Business M

- Page 99 and 100: Figure 3.2 Staff Organogram Plant M

- Page 101 and 102: 3.8.2 Alternative Site Location Sev

- Page 103 and 104: the next 20 years, the vast bulk of

- Page 105 and 106: climate but straddles the Tropical

- Page 107 and 108: The relative humidity of Nigeria is

- Page 109 and 110: 4.4 GEOLOGY The Study Area is locat

- Page 111 and 112: 4.5.1 Soil Types 4.5.2 Soil Quality

- Page 113 and 114: season and were observably lower du

- Page 115 and 116: increased with depth, showing a sig

- Page 117 and 118: subsoil (15.00 - 35.00 x 10 3 cfu/g

- Page 119 and 120: higher heterotrophic fungi concentr

- Page 121 and 122: The results of the inorganic and or

- Page 123 and 124: cfu/100ml at Orior-Osemwende during

- Page 125 and 126: Air quality measurements were taken

- Page 127 and 128: Figure 4.6 Sampling Locations for N

- Page 129 and 130: Sample Code Noise Level - dB (A) A7

- Page 131 and 132: Figure 4.7 Sampling Points ((Flora)

- Page 133 and 134: All flora habitats surveyed were fo

- Page 135 and 136: Figure 4.12 Fallow Land with Guinea

- Page 137 and 138: Figure 4.16 A view of re-growing se

- Page 139 and 140:

Figure 4.19 Plant Species Discorea

- Page 141 and 142:

Conservation Status Scientific Name

- Page 143 and 144:

Species identified in the project a

- Page 145 and 146:

Urho-Nisen-Urho-Nisen, which will b

- Page 147 and 148:

• Participation of those with acc

- Page 149 and 150:

Table 5.2 Key Socio-Economic Indica

- Page 151 and 152:

Figure 5.3 Age Distribution, Edo St

- Page 153 and 154:

were classed as vulnerable by virtu

- Page 155 and 156:

Orior-Osemwende Orior-Osemwende is

- Page 157 and 158:

the communities within the Project

- Page 159 and 160:

Figure 5.6 Traditional Leadership S

- Page 161 and 162:

conflict could be a problem in the

- Page 163 and 164:

There are distinct gender divisions

- Page 165 and 166:

Petty Trading According to FGDs som

- Page 167 and 168:

the house. Almost a quarter of hous

- Page 169 and 170:

have no formal schooling; while app

- Page 171 and 172:

Name of sacred site worshipped in c

- Page 173 and 174:

Figure 5.11 Map showing the locatio

- Page 175 and 176:

stretches of the walls and moats re

- Page 177 and 178:

Figure 5.14 The Location of Moats S

- Page 179 and 180:

native doctors or herbalists. With

- Page 181 and 182:

project and its potential impacts (

- Page 183 and 184:

The Project identified the Nigerian

- Page 185 and 186:

Figure 6.2 Community Engagement in

- Page 187 and 188:

Figure 6.6 Consultation with the Ed

- Page 189 and 190:

Details of the asset census survey

- Page 191 and 192:

Stakeholder Engagement Engagement A

- Page 193 and 194:

6.5 KEY ISSUES RAISED This section

- Page 195 and 196:

6.6 PROJECT GRIEVANCE MECHANISM Gri

- Page 197 and 198:

to ensure that projects can proceed

- Page 199 and 200:

7 BIOPHYSICAL AND SOCIO-ECONOMIC IM

- Page 201 and 202:

2. Evaluation of the importance (or

- Page 203 and 204:

In addition to predicted impacts, t

- Page 205 and 206:

Significance for Socio-economic Imp

- Page 207 and 208:

Table 7.2 Species Value / Sensitivi

- Page 209 and 210:

Box 7.4 Mitigation Hierarchy for Pl

- Page 211 and 212:

AERMOD is considered to be appropri

- Page 213 and 214:

Figure 7.2 Wind Roses for Bohicon,

- Page 215 and 216:

Country Averaging period Recommende

- Page 217 and 218:

The WHO guidelines are particularly

- Page 219 and 220:

7.3.5 Receptors per year for a sing

- Page 221 and 222:

7.3.6 Impact Description and Signif

- Page 223 and 224:

Process Emissions: NO x and CO The

- Page 225 and 226:

Figure 7.5 1 h maximum NO 2, the Pr

- Page 227 and 228:

7.3.9 Impact Description and Signif

- Page 229 and 230:

The values in Table 7.13 will there

- Page 231 and 232:

impacts exactly or take account of

- Page 233 and 234:

Figure 7.6 Operational noise levels

- Page 235 and 236:

also be required for the burial of

- Page 237 and 238:

7.5.4 Impact Description and Signif

- Page 239 and 240:

The impact of the Project on water

- Page 241 and 242:

7.6.4 Impact Description and Signif

- Page 243 and 244:

Artanema longifolium (a flowering p

- Page 245 and 246:

Table 7.18 Summary of Impact Signif

- Page 247 and 248:

The site will also generate general

- Page 249 and 250:

include estimates for the physical

- Page 251 and 252:

7.9.2 Impact Description and Signif

- Page 253 and 254:

7.10.2 Impact Description and Signi

- Page 255 and 256:

for impacts to demographics during

- Page 257 and 258:

As discussed above, and due to the

- Page 259 and 260:

Project’s construction phase will

- Page 261 and 262:

during decommissioning is expected

- Page 263 and 264:

Due to the high unemployment rate i

- Page 265 and 266:

contract workers. An additional num

- Page 267 and 268:

enefit the local communities. These

- Page 269 and 270:

impact on a small number of inhabit

- Page 271 and 272:

Besides the construction of the pla

- Page 273 and 274:

• Psychological impacts associate

- Page 275 and 276:

7.15.4 Impact Description and Signi

- Page 277 and 278:

Impact Significance The extent of t

- Page 279 and 280:

• Bitumen shall not be overheated

- Page 281 and 282:

8.2.2 Operation With the implementa

- Page 283 and 284:

• Oil interceptors and silt traps

- Page 285 and 286:

• All surface water or other cont

- Page 287 and 288:

• Reduce or prevent off-site sedi

- Page 289 and 290:

8.5.2 Operation • After construct

- Page 291 and 292:

8.6.2 Operation • Waste shall be

- Page 293 and 294:

8.8 ECONOMIC RESETTLEMENT As noted

- Page 295 and 296:

impacts over the operations period.

- Page 297 and 298:

Effective and ongoing implementatio

- Page 299 and 300:

• Frequent and regular disclosure

- Page 301 and 302:

8.12.2 Operational The mitigation m

- Page 303 and 304:

8.13.2 Operation reduce the potenti

- Page 305 and 306:

• Personal Protective Equipment (

- Page 307 and 308:

8.14.3 Decommissioning The health a

- Page 309 and 310:

Figure 9.1 Annual mean NO 2, cumula

- Page 311 and 312:

Table 9.1 Summary of cumulative imp

- Page 313 and 314:

impact is not due to the operation

- Page 315 and 316:

9.3 SOILS AND GEOLOGY The implement

- Page 317 and 318:

9.10 EMPLOYMENT AND ECONOMY The Pro

- Page 319 and 320:

10 ENVIRONMENTAL AND SOCIAL MANAGEM

- Page 321 and 322:

Table 10.1 Environmental Management

- Page 323 and 324:

10.2.2 Communication Azura Power wi

- Page 325 and 326:

The management of change procedure

- Page 327 and 328:

Impacts Management Plans Impacts to

- Page 329 and 330:

frequency of this reporting will be

- Page 331 and 332:

Ref # Potential impact Desired Outc

- Page 333 and 334:

Table 10.4 Construction Phase: Envi

- Page 335 and 336:

Ref # Potential impact contaminatio

- Page 337 and 338:

Ref # Potential impact Desired Outc

- Page 339 and 340:

Ref # Potential impact applied work

- Page 341 and 342:

Ref # Potential impact safety impac

- Page 343 and 344:

Table 10.5 Operational Phase: Envir

- Page 345 and 346:

Ref # Potential impact 3.4 Water Re

- Page 347 and 348:

Ref # Potential impact Desired Outc

- Page 349 and 350:

Ref # Potential impact 3.10 Impacts

- Page 351 and 352:

Ref # Potential impact 3.12 Potenti

- Page 353 and 354:

Ref # Potential impact Desired Outc

- Page 355 and 356:

Ref # Potential impact Desired Outc

- Page 357 and 358:

Ref # Potential impact Desired Outc

- Page 359 and 360:

Ref # Potential impact Desired Outc

- Page 361 and 362:

Ref # Potential impact Desired Outc

- Page 363 and 364:

impacts were considered to be negli

- Page 365 and 366:

Federal Environmental Protection Ag

- Page 367:

World Health Organization (2007) pH