- Page 1 and 2:

safety INTEGRATED Safety applicatio

- Page 3 and 4:

Safety Integrated Functional Exampl

- Page 5 and 6:

42 2.8 E-Stop with monitored start

- Page 7 and 8:

Structure and wiring An overview of

- Page 9 and 10:

Structure and wiring An overview of

- Page 11 and 12:

Structure and wiring An overview of

- Page 13 and 14:

Structure and wiring An overview of

- Page 15 and 16:

Structure and wiring An overview of

- Page 17 and 18:

Structure and wiring An overview of

- Page 19 and 20:

Structure and wiring An overview of

- Page 21 and 22:

Structure and wiring An overview of

- Page 23 and 24:

Structure and wiring An overview of

- Page 25 and 26:

Structure and wiring An overview of

- Page 27 and 28:

Required components Hardwarekompone

- Page 29 and 30:

Required components Hardware compon

- Page 31 and 32:

Structure and wiring An overview of

- Page 33 and 34:

Structure and wiring An overview of

- Page 35 and 36:

Structure and wiring An overview of

- Page 37 and 38:

Structure and wiring An overview of

- Page 39 and 40:

Structure and wiring An overview of

- Page 41 and 42:

Structure and wiring An overview of

- Page 43 and 44:

Structure and wiring An overview of

- Page 45 and 46:

Structure and wiring An overview of

- Page 47 and 48:

Structure and wiring An overview of

- Page 49 and 50:

Structure and wiring An overview of

- Page 51 and 52:

Structure and wiring An overview of

- Page 53 and 54:

Structure and wiring An overview of

- Page 55 and 56:

Required components Hardware compon

- Page 57 and 58:

Emergency Stop with monitored start

- Page 59 and 60:

Structure and wiring An overview of

- Page 61 and 62:

Required components Hardware compon

- Page 63 and 64:

Protective door monitoring with aut

- Page 65 and 66:

2 safety circuits in a cascade acco

- Page 67 and 68:

Components required Hardware compon

- Page 69 and 70:

Important hardware component settin

- Page 71 and 72:

Note Diagram Overload, thermal moto

- Page 73 and 74:

Required Components This chapter co

- Page 75 and 76:

Example Code This chapter describes

- Page 77 and 78:

Description Parameters The contacto

- Page 79 and 80:

Configuration validation Starting t

- Page 81 and 82:

Required Components This chapter co

- Page 83 and 84:

Example Code This chapter describes

- Page 85 and 86:

Description Parameters For the doub

- Page 87 and 88:

Commissioning the AS Interface Safe

- Page 89 and 90:

Protective door with door interlock

- Page 91 and 92:

Assembly and Wiring Overview of Har

- Page 93 and 94:

Example Code This chapter describes

- Page 95 and 96:

Description Parameters For the doub

- Page 97 and 98:

Commissioning the AS Interface Safe

- Page 99 and 100:

Protective door with door interlock

- Page 101 and 102:

Assembly and Wiring Overview of Har

- Page 103 and 104:

Example Code This chapter describes

- Page 105 and 106:

Description Parameters For the doub

- Page 107 and 108:

Commissioning the AS Interface Safe

- Page 109 and 110:

Protective door with door interlock

- Page 111 and 112:

Assembly and Wiring Overview of Har

- Page 113 and 114:

Example Code This chapter describes

- Page 115 and 116:

Description Parameters For the doub

- Page 117 and 118:

Commissioning the AS Interface Safe

- Page 119 and 120:

Protective door with door interlock

- Page 121 and 122:

Assembly and Wiring Overview of Har

- Page 123 and 124:

Example Code This chapter describes

- Page 125 and 126:

Description Parameters For the doub

- Page 127 and 128:

Commissioning the AS Interface Safe

- Page 129 and 130:

SIMOCODE pro direct starters with s

- Page 131 and 132:

Required Components Hardware compon

- Page 133 and 134:

Wiring of Hardware Components

- Page 135 and 136:

Note Screenshot SIMOCODE is inserte

- Page 137 and 138:

Parameter settings Note Screenshot

- Page 139 and 140:

Downloading the SIMOCODE pro projec

- Page 141 and 142:

The displayed link is parameterized

- Page 143 and 144:

SIMOCODE pro reversing starters wit

- Page 145 and 146:

Required Components Hardware compon

- Page 147 and 148:

Wiring of Hardware Components

- Page 149 and 150:

Note Screenshot SIMOCODE is inserte

- Page 151 and 152:

Parameter settings Note Screenshot

- Page 153 and 154:

Downloading the SIMOCODE pro projec

- Page 155 and 156:

The displayed link is parameterized

- Page 157 and 158:

SIMOCODE pro star-delta starters wi

- Page 159 and 160:

Required Components Hardware compon

- Page 161 and 162:

Wiring of Hardware Components

- Page 163 and 164:

Note Screenshot SIMOCODE is inserte

- Page 165 and 166:

Parameter settings Note Screenshot

- Page 167 and 168:

Downloading the SIMOCODE pro projec

- Page 169 and 170:

The displayed link is parameterized

- Page 171 and 172:

Fail-safe Controllers SIMATIC Safet

- Page 173 and 174:

Required components Hardware compon

- Page 175 and 176:

L1 N PE Note A connection between t

- Page 177 and 178:

Settings of the CPU 315F-2DP The se

- Page 179 and 180:

The sample code with the given conf

- Page 181 and 182:

Safety Door with Spring-Loaded Enga

- Page 183 and 184:

Required components Hardware compon

- Page 185 and 186:

L1 N PE PS 307 / CPU 315F L+ M IM 1

- Page 187 and 188:

Important hardware component settin

- Page 189 and 190:

Basic Performance Data Load and mai

- Page 191 and 192:

Note If the above section is not ob

- Page 193 and 194:

FB "COORDINATION" (FB1, DB1) After

- Page 195 and 196:

Safety Door with Magnetic Engagemen

- Page 197 and 198:

Setup and Wiring In order to set up

- Page 199 and 200:

Function test After wiring the hard

- Page 201 and 202:

Settings of the CPU 315F-2DP The se

- Page 203 and 204:

Basic Performance Data Load and mai

- Page 205 and 206:

FC "STANDARD" (FC 3) The FC "STANDA

- Page 207 and 208:

The safety door locks ("COIL"="1"),

- Page 209 and 210:

Safety Door without Guard Locking i

- Page 211 and 212:

Setup and Wiring In order to set up

- Page 213 and 214:

Function test After wiring the hard

- Page 215 and 216:

Settings of the CPU 315F-2DP The se

- Page 217 and 218:

Sample Code Preliminary Remarks Enc

- Page 219 and 220:

The acknowledgement for the enable

- Page 221 and 222:

Light Curtain in Category 4 with Mu

- Page 223 and 224:

Flow chart The flow chart below sho

- Page 225 and 226:

ACK PS 307 START CPU 315F Wiring of

- Page 227 and 228: Function test After wiring the hard

- Page 229 and 230: Set mode: "Test Mode" During Proces

- Page 231 and 232: Sample Code Preliminary Remarks Enc

- Page 233 and 234: FB "L_CURTAIN" (FB 1, DB 1) FB 1 ha

- Page 235 and 236: Two-Hand Control Panel with Integra

- Page 237 and 238: Required components Hardware compon

- Page 239 and 240: L1 N PE PS 307 / CPU 315F L+ M IM 1

- Page 241 and 242: Important hardware component settin

- Page 243 and 244: Settings of the failsafe F-DO The s

- Page 245 and 246: F-CALL (FC1) F-CALL (FC1) is the F

- Page 247 and 248: Integration of the Readback Signal

- Page 249 and 250: Setup and Wiring In order to set up

- Page 251 and 252: L1 N PE PS 307 / CPU 315F L+ M AUX1

- Page 253 and 254: Important hardware component settin

- Page 255 and 256: Settings of the failsafe F-DO The s

- Page 257 and 258: Sample Code Preliminary Remarks Enc

- Page 259 and 260: Warning! When using the F applicati

- Page 261 and 262: Safety Shutdown in the Stop Categor

- Page 263 and 264: G_FB_XX_152 Time sequence for Stop

- Page 265 and 266: Setup and Wiring Regarding the use

- Page 267 and 268: Parameters used Below, some charact

- Page 269 and 270: L1 N PE PS 307 / CPU 315F A4 2 DO H

- Page 271 and 272: Function test The inputs and output

- Page 273 and 274: Set mode: "Test Mode" During Proces

- Page 275 and 276: Sample Code Preliminary Remarks Enc

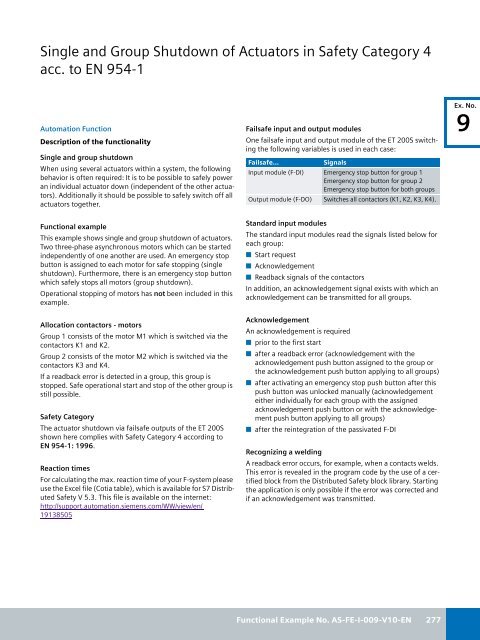

- Page 277: Network 2 FB "Safety_PRG" (FB1, DB1

- Page 281 and 282: Required components Hardware compon

- Page 283 and 284: Note The DP interface of the CPU 31

- Page 285 and 286: The terminal markings of the load c

- Page 287 and 288: Important hardware component settin

- Page 289 and 290: Settings of the failsafe F-DO The s

- Page 291 and 292: COND2), which can be changed by the

- Page 293 and 294: Please consider the following notes

- Page 295 and 296: 7 Cyclic input data 0 OSSD Warning!

- Page 297 and 298: Time sequence For a better understa

- Page 299 and 300: Advantages/customer benefits ■ Fo

- Page 301 and 302: IM 151 HF IM 151 HF PM-E PM-E 2DI H

- Page 303 and 304: Connection of the LS4 Integrating t

- Page 305 and 306: No. Instruction Note 8 Click "Cance

- Page 307 and 308: Function test After wiring the hard

- Page 309 and 310: Important hardware component settin

- Page 311 and 312: Settings of the fail-safe F-DO The

- Page 313 and 314: Sample Code Preliminary Remarks Enc

- Page 315 and 316: FB "SET_ACT" (FB 3, DB 3) Network 1

- Page 317 and 318: #SEN_FIELD 1 #SEN_FIELD 2 #SEN_FIEL

- Page 319 and 320: Passivation and Reintegration of F-

- Page 321 and 322: Setup and Wiring This chapter descr

- Page 323 and 324: Overview of inputs and outputs Over

- Page 325 and 326: Important hardware component settin

- Page 327 and 328: "Channel 1.5": "Evaluation of the s

- Page 329 and 330:

Sample Code In this chapter you lea

- Page 331 and 332:

Scenario: Manual reintegration Disc

- Page 333 and 334:

Scenario: F-communication error Dis

- Page 335 and 336:

Overview of buttons and indicator l

- Page 337 and 338:

Explanations for the STEP 7 program

- Page 339 and 340:

FB2 / Network 1 DB818.DBX 36.4 Over

- Page 341 and 342:

Description: FB3, DB4 (REINTEGRATIO

- Page 343 and 344:

FB3 / Netzwerk 3 Overview of the si

- Page 345 and 346:

Operation: Normal operation Operati

- Page 347 and 348:

Operation: Automatic reintegration

- Page 349 and 350:

Background Knowledge on the Functio

- Page 351 and 352:

F-I/O-module data block What is an

- Page 353 and 354:

The user has read and write access

- Page 355 and 356:

Passivation (of entire module or ch

- Page 357 and 358:

How is the "passivation of channels

- Page 359 and 360:

Processes during passivation and re

- Page 361 and 362:

Process: Channel / module error (ma

- Page 363 and 364:

Process: Safety program Preconditio

- Page 365 and 366:

Warning Automatic reintegration is

- Page 367 and 368:

This communication is realized via

- Page 369 and 370:

DP Slave (MASTERDRIVES) The descrip

- Page 371 and 372:

Emergency stop Time Explanation t1

- Page 373 and 374:

Required Components Hardware compon

- Page 375 and 376:

Notes on configuring MASTERDRIVES N

- Page 377 and 378:

Inputs and outputs used for the DP

- Page 379 and 380:

Overview hardware configuration of

- Page 381 and 382:

Settings of the fail-safe F-DI The

- Page 383 and 384:

Basic Performance Data DP Master: L

- Page 385 and 386:

Program sequence General overview T

- Page 387 and 388:

Symbol Function Explanation START P

- Page 389 and 390:

Network 4: Reading in the readback

- Page 391 and 392:

Variables of FB "STANDSTILL_AND_SAF

- Page 393 and 394:

Network 10 In this network, the tim

- Page 395 and 396:

Network 2 With OUT3=0 the drive is

- Page 397 and 398:

Safety Drives System 1 SAFE STANDST

- Page 399 and 400:

Behavior when Emergency Stop is iss

- Page 401 and 402:

Behavior when Emergency Stop is iss

- Page 403 and 404:

Behavior when the protective doors

- Page 405 and 406:

Function description A structure in

- Page 407 and 408:

Behavior when Emergency Stop is iss

- Page 409 and 410:

Behavior when Emergency Stop is iss

- Page 411 and 412:

■ This circuit principle is suita

- Page 413 and 414:

Certificate The examples shown in t

- Page 415 and 416:

Behavior when Emergency Stop is iss

- Page 417 and 418:

Behavior when Emergency Stop is iss

- Page 419 and 420:

Behavior when the protective doors

- Page 421 and 422:

Behavior when the protective doors

- Page 423 and 424:

Behavior when Emergency Stop is iss

- Page 425 and 426:

Behavior when Emergency Stop is iss

- Page 427 and 428:

■ This circuit principle is suita

- Page 429 and 430:

Certificate The examples shown in t

- Page 431 and 432:

"Safe standstill" with SINAMICS usi

- Page 433 and 434:

"Safety Integrated" settings The de

- Page 435 and 436:

Behavior, when the protective doors

- Page 437 and 438:

Behavior at Emergency Stop Emergenc

- Page 439 and 440:

The safety requirements are fulfill

- Page 441 and 442:

Hardware components for the F-CPU c

- Page 443 and 444:

Overview of interfaces and communic

- Page 445 and 446:

Overview of the network configurati

- Page 447 and 448:

SINAMICS Runtime System Parametizat

- Page 449 and 450:

SIMOTION Runtime System Starting up

- Page 451 and 452:

SIMATIC Runtime System Function Blo

- Page 453 and 454:

Overview of the function block "F_D

- Page 455 and 456:

Überwachung auf sicher red. Geschw

- Page 457 and 458:

Plausibility check: Motion command

- Page 459 and 460:

Porting PROFIsafe to the applicatio

- Page 461 and 462:

Input signal conditioning The incom

- Page 463 and 464:

TÜV certificate (issued by the TUE

- Page 465 and 466:

SINAMICS G120 - controlled via PROF

- Page 467 and 468:

Required components An overview of

- Page 469 and 470:

Connecting-up the hardware componen

- Page 471 and 472:

Fault 395 (acceptance test / acknow

- Page 473 and 474:

Overview of inputs and outputs Simu

- Page 475 and 476:

Download S7 program To download the

- Page 477 and 478:

nels takes approximately 2.4s. This

- Page 479 and 480:

Please note that the two actual che

- Page 481 and 482:

Key performance data Load memory an

- Page 483 and 484:

The individual telegram components

- Page 485 and 486:

DB1, axis_DB The axis_DB represents

- Page 487 and 488:

SINAMICS G120 parameterization In o

- Page 489 and 490:

SINAMICS G120 - controlled via PROF

- Page 491 and 492:

Required components An overview of

- Page 493 and 494:

Connecting-up the hardware componen

- Page 495 and 496:

Fault 395 (acceptance test / acknow

- Page 497 and 498:

Overview of inputs and outputs Simu

- Page 499 and 500:

■ Then, in the Project Navigator

- Page 501 and 502:

Safe Stop 1 (SS1) tab The parameter

- Page 503 and 504:

Function test The function test can

- Page 505 and 506:

Siemens telegram 352, PZD 6/6 The s

- Page 507 and 508:

Principle structure of the FC100 Ne

- Page 509 and 510:

Functional Example No. SD-FE-I-002-

- Page 511 and 512:

Contact partners Contact partners f