2002 Swinburne TAFE Handbook - Swinburne University of ...

2002 Swinburne TAFE Handbook - Swinburne University of ...

2002 Swinburne TAFE Handbook - Swinburne University of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

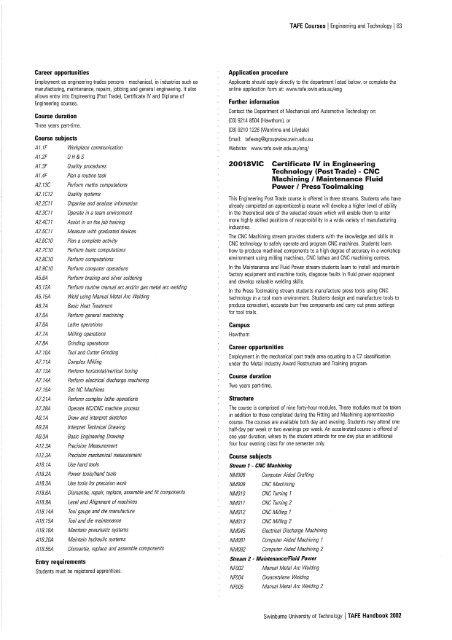

<strong>TAFE</strong> Courses 1 Engineering and Technology 183<br />

Career opportunities<br />

Employment as engineering trades persons - mechanical, in industries such as<br />

manufacturing, maintenance, repairs, jobbing and general engineering. It also<br />

allows entry into Engineering (Post Trade), Certificate IV and Diploma <strong>of</strong><br />

Engineering courses.<br />

Course duration<br />

Three years part-time.<br />

Course subjects<br />

A 1.1 F<br />

Al.2F<br />

AUF<br />

Al.4F<br />

A2.13C<br />

A2.1C12<br />

A2.2Cll<br />

A2.3Cll<br />

A2.4Cll<br />

A2.5Cll<br />

A2.6Cl0<br />

A2.7ClO<br />

A2.8Cl0<br />

A2.BC10<br />

A5.6A<br />

A5.12A<br />

A5.15A<br />

A6.7A<br />

A7.5A<br />

A7.6A<br />

A7.7A<br />

A7.8A<br />

AliDA<br />

A7.11A<br />

A113A<br />

A7.14A<br />

A115A<br />

A7.21A<br />

A7.28A<br />

AB.1A<br />

AB.2A<br />

AB.3A<br />

A 12.3A<br />

A 12.3A<br />

A18.1A<br />

A 18.2A<br />

A 18.3A<br />

A 18.6A<br />

A 18.BA<br />

A18.14A<br />

A18.15A<br />

A18.18A<br />

A 18.20A<br />

A 18.55A<br />

Workplace communication<br />

OH&S<br />

Quality procedures<br />

Plan a routine task<br />

Perform maths computations<br />

Quality systems<br />

Organise and analyse information<br />

Operate in a team environment<br />

Assist in on the job training<br />

Measure with graduated devices<br />

Plan a complete activity<br />

Perform basic computations<br />

Perform computations<br />

Perform computer operations<br />

Perform brazing and silver soldering<br />

Perform routine manual arc and/or gas metal arc welding<br />

Weld using Manual Metal Arc Welding<br />

Basic Heat Treatment<br />

Perform general machining<br />

Lathe operations<br />

Milling operations<br />

Grinding operations<br />

Tool and Cutter Grinding<br />

Complex Milling<br />

Perform horizontal/vertical boring<br />

Perform electrical discharge machining<br />

Set NC Machines<br />

Perform complex lathe operations<br />

Operate NC/CNC machine process<br />

Draw and interpret sketches<br />

Interpret Technical Drawing<br />

Basic Engineering Drawing<br />

Precision Measurement<br />

Precision mechanical measurement<br />

Use hand tools<br />

Power tools/hand tools<br />

Use tools for precision work<br />

Dismantle, repair, replace, assemble and fit components<br />

Level and Alignment <strong>of</strong> machines<br />

Tool gauge and die manufacture<br />

Tool and die maintenance<br />

Maintain pneumatic systems<br />

Maintain hydraulic systems<br />

Dismantle, replace and assemble components<br />

Entrv requirements<br />

Students must be registered apprentices.<br />

Application procedure<br />

Applicants should apply directly to the department listed below, or complete the<br />

online application form at: www.tafe.swin.edu.au/eng<br />

Further information<br />

Contact the Department <strong>of</strong> Mechanical and Automotive Technology on:<br />

(03)92148504 (Hawthorn), or<br />

(03) 9210 1226 (Wantirna and Lilydale)<br />

Email: tafeeng@groupwise.swin.edu.au<br />

Website: www.tafe.swin.edu.au/eng/<br />

20018VIC<br />

Certificate IV in Engineering<br />

Technology (Post Trade) - CNC<br />

Machining I Maintenance Fluid<br />

Power I Press Toolmaking<br />

This Engineering Post Trade course is <strong>of</strong>fered in three streams. Students who have<br />

already completed an apprenticeship course will develop a higher level <strong>of</strong> ability<br />

in the theoretical side <strong>of</strong> the selected stream which will enable them to enter<br />

more highly skilled positions <strong>of</strong> responsibility in a wide variety <strong>of</strong> manufacturing<br />

industries.<br />

The CNC Machining stream provides students with the knowledge and skills in<br />

CNC technology to safely operate and program CNC machines. Students learn<br />

how to produce machined components to a high degree <strong>of</strong> accuracy in a workshop<br />

environment using milling machines, CNC lathes and CNC machining centres.<br />

In the Maintenance and Fluid Power stream students learn to install and maintain<br />

factory equipment and machine tools, diagnose faults in fluid power equipment<br />

and develop valuable welding skills.<br />

In the Press Toolmaking stream students manufacture press tools using CNC<br />

technology in a tool room environment. Students design and manufacture tools to<br />

produce consistent. accurate burr free components and carry out press settings<br />

for tool trials.<br />

Campus<br />

Hawthorn<br />

Career opportunities<br />

Employment in the mechanical post trade area equating to a C7 classification<br />

under the Metal Industry Award Restructure and Training program.<br />

Course duration<br />

Two years part-time.<br />

Structure<br />

The course is comprised <strong>of</strong> nine forty-hour modules. These modules must be taken<br />

in addition to those completed during the Fitting and Machining apprenticeship<br />

course. The courses are available both day and evening. Students may attend one<br />

half-day per week or two evenings per week. An accelerated course is <strong>of</strong>fered <strong>of</strong><br />

one year duration, where by the student attends for one day plus an additional<br />

four hour evening class for one semester only.<br />

Course subjects<br />

Stream 1 - CNC Machining<br />

NM006 Computer Aided Drafting<br />

NMOOB CNC Machining<br />

NM010 CNC Turning 1<br />

NMOl1 CNC Turning 2<br />

NM012 CNCMilling 1<br />

NM013 CNC Milling 2<br />

NM045 Electrical Discharge Machining<br />

NM081 Computer Aided Machining 1<br />

NM082 Computer Aided Machining 2<br />

Stream 2 - MaintenancelFluid Power<br />

NF002 Manual Metal Arc Welding<br />

NF004 Oxyacetylene Welding<br />

NF005 Manual Metal Arc Welding 2<br />

<strong>Swinburne</strong> <strong>University</strong> <strong>of</strong> Technology 1 <strong>TAFE</strong> <strong>Handbook</strong> <strong>2002</strong>