Small Decentralized Hydropower Program National ... - Cd3wd.com

Small Decentralized Hydropower Program National ... - Cd3wd.com

Small Decentralized Hydropower Program National ... - Cd3wd.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mercado<br />

Implicaciones de casta<br />

9 Ingreso en las Villas: Promedio por vivienda<br />

Fuente<br />

* Actitud Hacia la Electrification<br />

9 Posibilidades de Propiedad<br />

e Mapa de la Villa: indicando bloques de chozas,<br />

campos de cultivo, y division<br />

de casta y distribution por<br />

oficio.<br />

9 Agua Potable: fuente, distancia, cantidad por<br />

cabeza, medios de transporte.<br />

Se evaluo el potential de la carga dentrode un<br />

radio dei km de un sitio tipico para determinar el<br />

consumo electric0 potential existente. En este tirea<br />

en particular hay 1,200 personas en 200 viviendas.<br />

Demanda Existente<br />

1. Molienda de harina a l/2 kglpersonaldia (max)<br />

= 600 kg. Un molino (disponible de inmediato)<br />

proporcionatia 100 kglhora requiriendo 6 horas<br />

a 3.75 kW.<br />

2. Extraccibn de aceite: el consumo de 112<br />

litrolcabezalmes es equivalente a 20 litros por<br />

dia (16 kg). Con un rendimiento de 30% un<br />

extractor de 3 hp trabajando a una capacidad de<br />

15/kg/hors necesitaria operar- 4 horas al dia.<br />

3. Descascaramiento de arrow: Se asume que el<br />

consumo es de l/4 kgldialcabeza = 300<br />

kg/&a = 460 kg arroz (a la conversion tipica de<br />

65%). Una maquina de 5 hp que procesara 200<br />

kg de arroz por hora, requiere operation por 2 9’2<br />

horas a 3.75 kW.<br />

4. Iiuminacidn Ekctrica: Potential 200 viviendas<br />

x 2 focos @ 40 W x 3 horas didrias = 48 kWh<br />

@W.<br />

Demanda Promotional<br />

1. Suministro domkstico de agua: Para esta villa<br />

se calculo 30 litros por dia. (36,000 litros<br />

elevados a 400 pies a una eficiencia de 75%) en<br />

cuatro horas mediante una bomba a motor de 6<br />

hp = 4.5 kW x 4 horas.<br />

2. Aserradero: Para fabricar cajas de empaque<br />

para frutas, el plan es un aserradero de 5 hp<br />

trabajando seis horas al dia = 6 x 3.75 kW.<br />

3. Irrigacibn par elevacibn: Se requiere u.na<br />

bomba para proporcionar 5 cm de agua sobre<br />

40 hectireas por mes durante seis meses a una<br />

ctida de 60 metros. Este requisito demanda una<br />

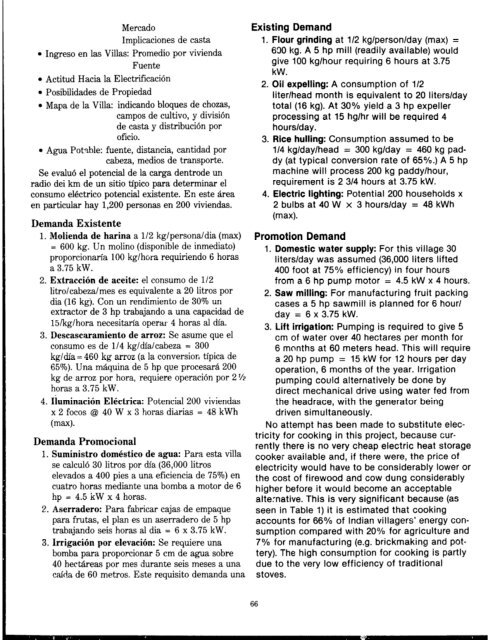

Existing Demand<br />

1. Flour grinding at 112 kg/person/day (max) =<br />

630 kg. A 5 hp mill (readily available) would<br />

give 100 kg/hour requiring 6 hours at 3.75<br />

kW.<br />

2. Oil expelling: A consumption of 112<br />

liter/head month is equivalent to 20 liters/day<br />

total (16 kg). At 30% yield a 3 hp expeller<br />

processing at 15 hglhr will be required 4<br />

hours/day.<br />

3. Rice hulling: Consumption assumed to be<br />

114 kg/day/head = 300 kg/day = 460 kg pad-<br />

dy (at typical conversion rate of 65%.) A 5 hp<br />

machine will process 200 kg paddy/hour,<br />

requirement is 2 314 hours at 3.75 kW.<br />

4. Electric lighting: Potential 200 households x<br />

2 bulbs at 40 W x 3 hours/day = 48 kWh<br />

(max).<br />

Promotion Demand<br />

1. Domestic water supply: For this village 30<br />

liters/day was assumed (36,000 liters lifted<br />

400 foot at 75% efficiency) in four hours<br />

from a 6 hp pump motor = 4.5 kW x 4 hours.<br />

2. Saw milling: For manufacturing fruit packing<br />

cases a 5 hp sawmill is planned for 6 hour/<br />

day = 6 x 3.75 kW.<br />

3. Lift irrigation: Pumping is required to give 5<br />

cm of water over 40 hectares per month for<br />

6 months at 60 meters head. This will require<br />

a 20 hp pump = 15 kW for 12 hours per day<br />

operation, 6 months of the year. Irrigation<br />

pumping could alternatively be done by<br />

direct mechanical drive using water fed from<br />

the headrace, with the generator being<br />

driven simultaneously.<br />

No attempt has been made to substitute elec-<br />

tricity for cooking in this project, because cur-<br />

rently there is no very cheap electric heat storage<br />

cooker available and, if there were, the price of<br />

electricity would have to be considerably lower or<br />

the cost of firewood and cow dung considerably<br />

higher before it would be<strong>com</strong>e an acceptable<br />

alternative. This is very significant because (as<br />

seen in Table 1) it is estimated that cooking<br />

accounts for 66% of Indian villagers’ energy con-<br />

sumption <strong>com</strong>pared with 20% for agriculture and<br />

7% for manufacturing (e.g. brickmaking and pot-<br />

tery). The high consumption for cooking is partly<br />

due to the very low efficiency of traditional<br />

stoves.<br />

66

![Mum, int. [man] - Cd3wd.com](https://img.yumpu.com/51564724/1/190x134/mum-int-man-cd3wdcom.jpg?quality=85)